The Deformation Control Of Carburized Gear Heat Treatment

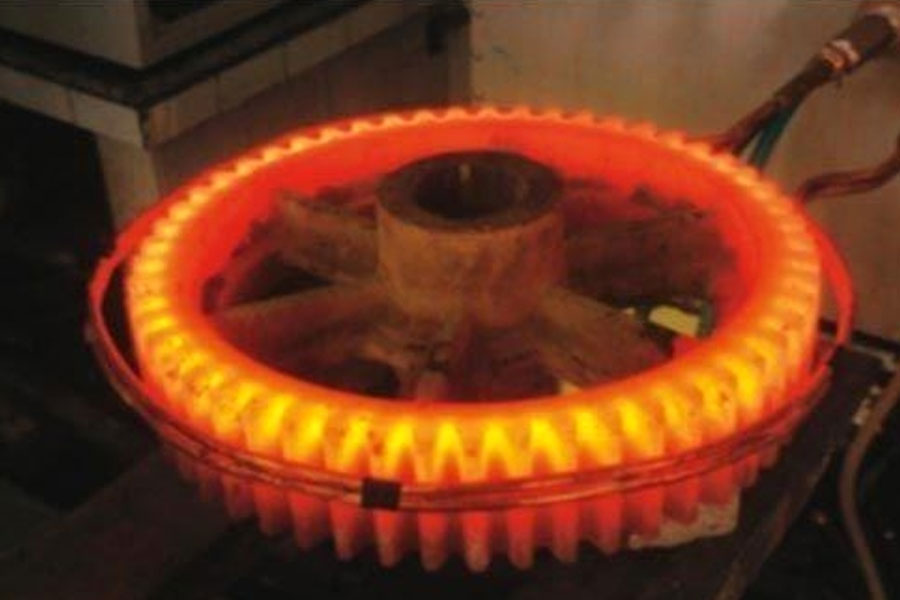

Heat treatment deformation of carburized gear. Heat treatment deformation directly affects the accuracy, strength, noise and life of the gear. Even if the gear grinding process is added after the carburizing heat treatment, the deformation still reduces the accuracy level of the gear. ...