Stainless Steel Casting

Stainless Steel Casting Services – Custom Casting Stainless Steel Alloy Parts China Company

IATF 16949 CERTIFIED CAST MANUFACTURING FOR SUS CASTINGS

What Is Stainless steel Casting? Stainless steel precision casting or investment casting, silica sol process. It is a low-cut or no-cutting casting process. It is an excellent process technology in the foundry industry. It has a wide range of applications. It is not only suitable for casting of various types and alloys, but also produces castings with dimensional accuracy, The surface quality is higher than other casting methods, and even the complex, high-temperature resistant, and difficult-to-process castings that are difficult to cast by other casting methods can be cast by investment casting.

Benefits of Stainless Steel Material (Casting Stainless Steel Parts):

- Very high tensile strength

- Excellent wear and corrosion resistance

- Good formability and weldability

- Hygienic with excellent cleanability

- Good performance at high/low temperatures

If you are seeking a professional casting supplier to provide high quality investment casting Stainless Steel parts, Minghe is one of the most affordable and capable manufacturer, specializing in Stainless Steel investment casting process on advanced casting equipment. With great experience and broad knowledge, our casting equipment can reach extremely tight tolerances in mass manufacturing stainless steel investment casting parts & products. Our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of investment casting to to meet your design specification, while optimize your time and cost.We work with a large selection of stainless steel types to produce everything and custom lost wax casting on the stainless steel parts for multiple industries. Please contact us for specific sus materials casting and machining.

Contact our stainless steel casting part engineer today to discuss the specifics of your complex projects.

Stainless Steel Investment Casting

As early as 1910, it was discovered that when the Cr content in steel exceeds 12%, it has good corrosion and oxidation resistance. In addition to containing more than 12% Cr, typical stainless steel also contains one or more other alloying elements, such as Ni, Mo, Cu, Nb, Ti, and N2.

Stainless steel casting is not only suitable for casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other casting methods. Even other casting methods are difficult to cast complex, high temperature resistant, and difficult to process castings. , Can be cast by investment casting.

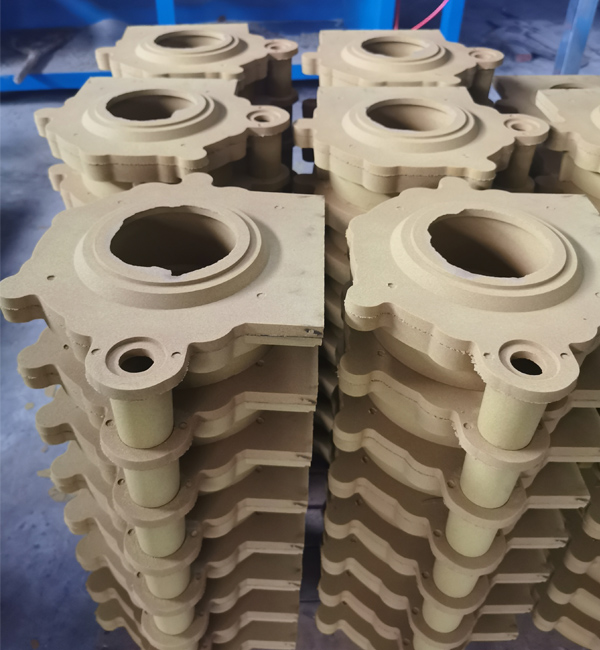

The so-called investment casting process is simply to use fusible materials (such as wax or plastic) to make a fusible model (referred to as investment or model), apply several layers of special refractory coatings on it, and then dry and harden it. After forming an integral shell, use steam or hot water to melt the model from the shell, then put the shell in the sand box, fill the mold with dry sand around it, and finally put the mold in the roasting furnace through high temperature Roasting (if a high-strength mold is used, the mold shell after demolding can be directly fired without modeling). After the mold or mold is fired, molten metal is poured into it to obtain a casting.

The dimensional accuracy of investment castings is relatively high, generally up to CT4-6 (CT10~13 for sand casting and CT5~7 for die casting). Of course, due to the complex process of investment casting, there are many factors that affect the dimensional accuracy of castings, such as molds. The shrinkage of the material, the deformation of the investment mold, the linear change of the shell in the heating and cooling process, the shrinkage of the alloy and the deformation of the casting during the solidification process, etc., so the dimensional accuracy of ordinary investment castings is high, but its Consistency still needs to be improved (the size consistency of castings with medium and high temperature waxes should be improved a lot).

When pressing the investment mold, the pressure type with high surface smoothness of the cavity is used, so the surface smoothness of the investment mold is also relatively high. In addition, the shell is made of a refractory coating made of a special high-temperature adhesive and a refractory material, which is coated on the investment mold, and the inner surface of the cavity that is in direct contact with the molten metal has a high smoothness. Therefore, the surface finish of investment castings is higher than that of general castings, generally reaching Ra.1.6~3.2μm.

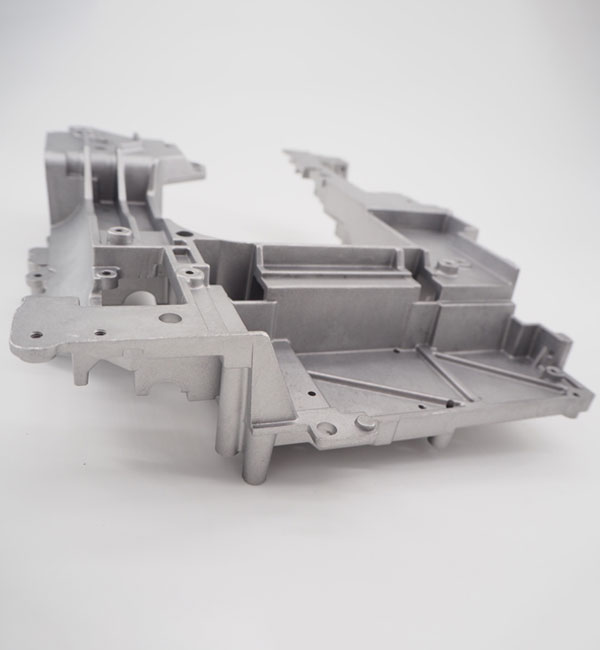

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, machining work can be reduced, but only a small amount of machining allowance can be left on the parts with higher requirements, and even some castings only have Leave a grinding and polishing allowance, and it can be used without mechanical processing. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

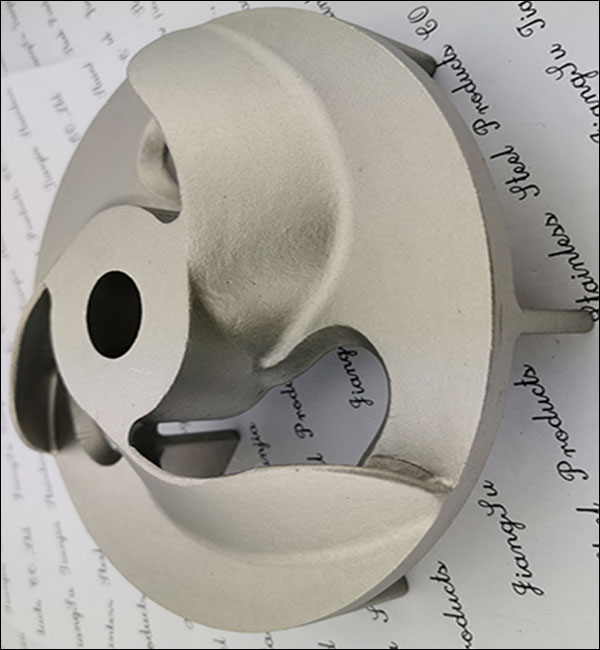

Another advantage of the investment casting method is that it can cast complex castings of various alloys, especially high-temperature alloy castings. For example, the blade of a jet engine, its streamlined profile and cooling cavity, can hardly be formed by machining technology. Production by investment casting process can not only achieve mass production, ensure the consistency of castings, but also avoid the stress concentration of residual knife marks after machining.

The Casting Material Of Stainless Steel

Cast stainless steel can generally be divided into three categories, namely, medium and high-strength martensitic stainless steel for engineering structures, corrosion-resistant stainless steel and heat-resistant stainless steel.

- Medium And High-Strength Martensitic Stainless Steel: including martensitic stainless steel and precipitation hardening stainless steel. In engineering applications, mechanical properties are the main indicator, and it is resistant to atmospheric media and milder corrosive media (such as water and certain organic substances) Good corrosion. The metallographic structure is low-carbon lath martensite.

- Corrosion-Resistant Stainless Steel: also known as stainless and acid-resistant steel. It mainly evaluates its corrosion resistance. It can be divided into two categories: chromium stainless steel and nickel-chromium stainless steel. The main factors affecting the corrosion resistance of stainless steel are the carbon content and the amount of precipitated carbides. Carbon is generally very low, usually less than 0.08%.

- Heat-Resistant Stainless Steel: For heat-resistant stainless steel, since the high-temperature mechanical properties depend on the stable carbide precipitation phase in the steel, the carbon content is higher than that of the corrosion-resistant steel, about 0.20% or more. The heat-resistant temperature of high-alloy heat-resistant steel castings can reach above 650℃

Precision investment casting stainless steel parts are becoming a choice for many industries due to its desirable physical properties! Stainless Steel is one of the most popular industrial alloys for many casting projects, due to its excellent physical properties. The below benefits have made Stainless Steel parts and products a viable choice for many industries and applications, though they are particularly favored in the medical, automotive, aerospace, healthcare and consumer electronics spheres. While the best and fastest way to mass make Stainless Steel parts is investment casting especially casting with corrosion resistant stainless steel reach far and wide.

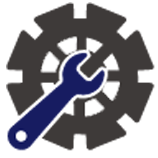

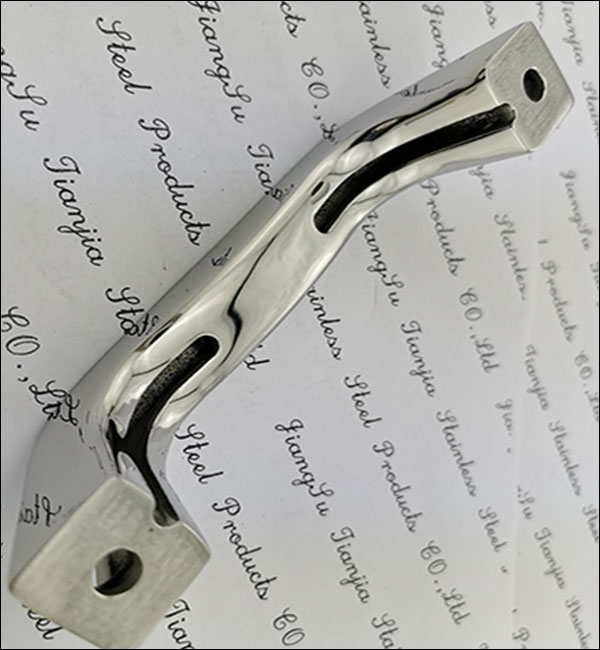

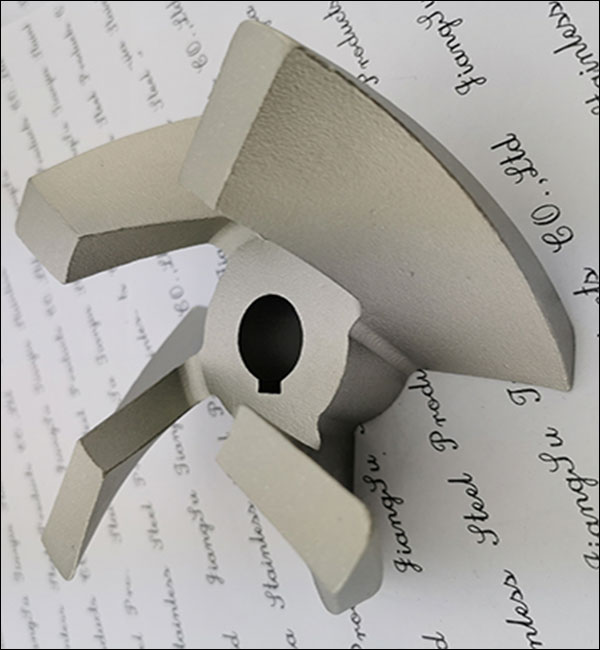

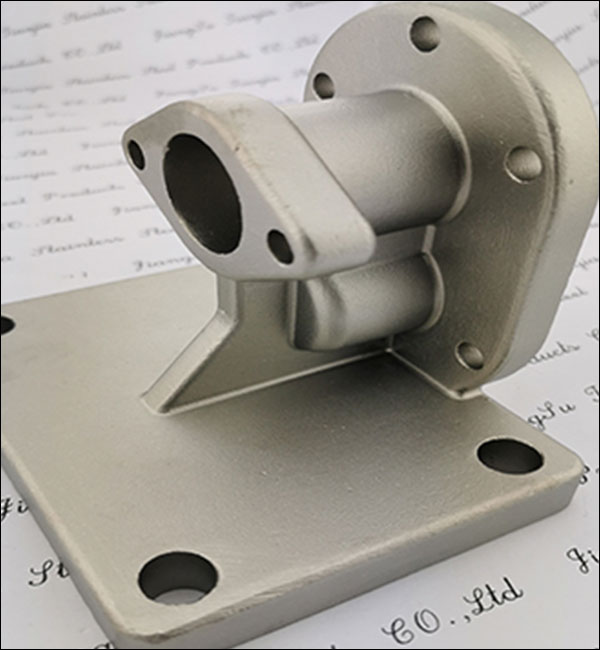

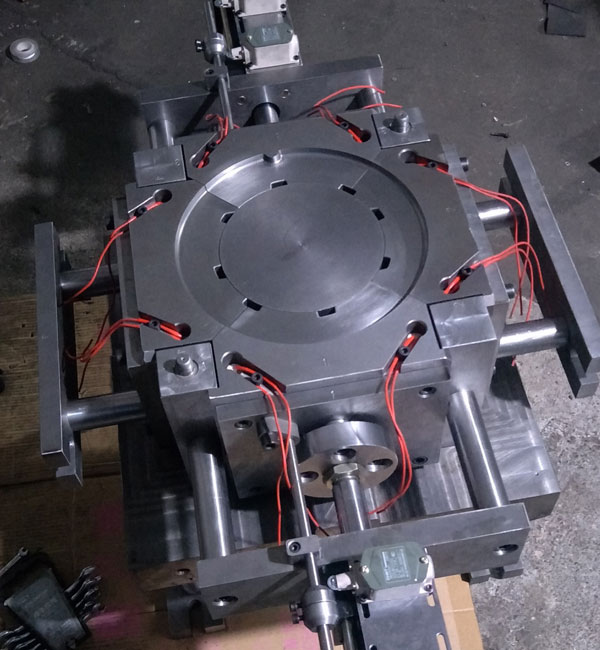

The Minghe Case Studies Of Stainless Steel Casting

Minghe Casting fabrication services are available for both design to reality and low to high volume production runs of your aluminum casting parts,zinc casting parts,magnesium casting,titanium casting parts,stainless steel casting parts,copper casting parts,steel casting parts, brass casting parts and more.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Stainless Steel Casting Supplier

Currently, our stainless steel casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom stainless steel casting fabrication service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your stainless steel casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.

Vacuum Casting

Vacuum Casting is a casting process in which metal is smelted, poured and crystallized in a vacuum chamber. Vacuum casting can minimize the gas content in the metal and prevent metal oxidation. This method can produce very demanding special alloy steel castings and extremely easily oxidized titanium alloy castings. Minghe Casting has a vacuum casting sub-factory, which is enough to solve all the problems related to vacuum casting