Brass Casting

Brass Casting Services – Custom Casting Brass Alloy Parts China Company

IATF 16949 CERTIFIED CAST MANUFACTURING FOR BRASS CASTINGS

What Is Copper Casting? Copper alloy with zinc as the main alloying element is usually called brass. The copper-zinc binary alloy is called ordinary brass, and the ternary, quaternary or multi-element brass formed by adding a small amount of other elements to the copper-zinc alloy is called special brass.Casting brass is a casting alloy based on Cu-Zn binary alloy. Its crystallization temperature interval is small and its casting performance is better. Compared with tin bronze, cast brass has higher mechanical properties. In addition, because brass contains a large amount of zinc, the cost is lower. These are the reasons why cast brass is widely used.

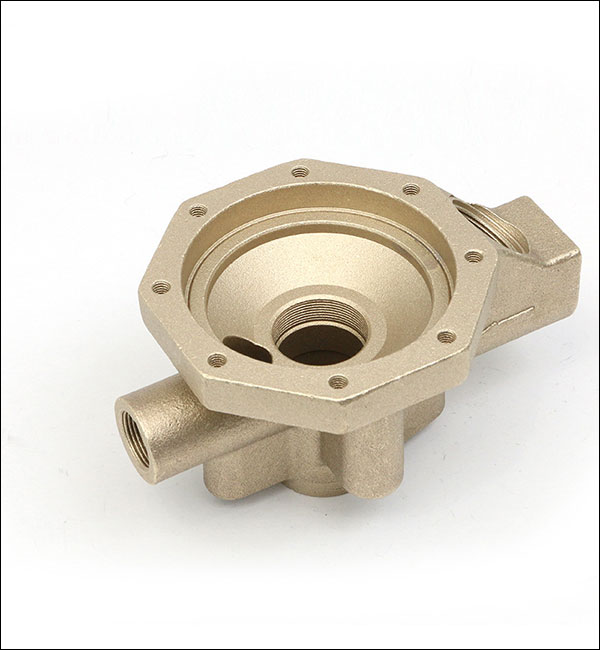

Casting brass is used to produce brass for castings. Brass castings are widely used in machinery manufacturing, ships, aviation, automobiles, construction and other industrial sectors, and occupy a certain weight in heavy non-ferrous metal materials, forming a cast brass series.The advantages of the brass casting process: low manufacturing cost, high process flexibility, complex shapes and large castings can be obtained, and occupy a large proportion in mechanical manufacturing, such as machine tools accounting for 60 to 80%, automobiles accounting for 25%, and tractors accounting for 25%. 50~60%.

Looking for brass parts customized by an experienced and reliable casting components manufacturer? Minghe’s custom brass casting services can be your ideal choice. We have over 30 years of casting experience, have capabilities to mass manufacture simple or complex brass products including high quality brass die casting components, brass investment casting components, brass centrifugal casting components, brass sand casting components and brass lost foam casting components to meet your demands with reliable operators, sophisticated machinery and equipment at our disposal. All of our brass casting components are subject to our rigorous inspection regime with designated inspectors, in-process inspection and a full final inspection completed on every part.

Contact our brass casting part engineer today to discuss the specifics of your complex projects.

The Casting Performance Comparison Between Brass And Bronze

Compared with brass and bronze, the solid solubility of zinc in copper is very large. Under normal temperature equilibrium, about 37% of zinc can be dissolved in copper, and about 30% of zinc can be dissolved in the as-cast state, while tin bronze In the as-cast state, the solid solubility mass fraction of tin in copper is only 5% to 6%, and the solid solubility mass fraction of aluminum bronze and aluminum in copper is only 7% to 8%. Therefore, zinc is very important in copper. Good solid solution strengthening effect. At the same time, most of the alloying elements can also be dissolved in brass to varying degrees, further improving its mechanical properties, which makes brass, especially some special brass, have the characteristics of high strength, and the price of zinc It is lower than aluminum, copper, and tin, and has rich resources.

The amount of zinc added in brass is more, so the cost of brass is lower than tin bronze and aluminum bronze. Brass has a small solidification temperature range, good fluidity, and convenient smelting. Because brass has the above-mentioned characteristics of high strength, low price and good casting performance, brass has more varieties, larger output and wider application than tin bronze and aluminum bronze in copper alloys. But the wear resistance and corrosion resistance of brass are not as good as bronze, especially the corrosion resistance and wear resistance of ordinary brass are relatively low. Only when some alloy elements are added to form a variety of special brass, its wear resistance and resistance Corrosion performance has been improved and improved.

The Casting Performance Characteristics Of Brass

The casting performance characteristics of cast brass are: zinc in cast brass is the main factor affecting the casting performance of cast brass. The vaporization point of zinc is about 907℃, and the melting point of cast brass is about 900℃. , Zinc has a great tendency to evaporate and oxidize. Casting brass has good fluidity, but manganese brass shrinks greatly, and it is prone to shrinkage, cold cracking and deformation.

In view of the above characteristics, the following process measures should be taken during casting:

- - Choose a sand core with good concession to reduce casting stress and prevent cracks and deformation.

- - Set up the riser to strengthen the feeding.

- - The gating system should be set up to ensure the realization of directional solidification, the slag collection and slag retaining structure should be set up, and the liquid flow should be filled smoothly. The inner runner layout should make the castings evenly cooled.

- - The pouring process minimizes the pouring temperature of cast brass to reduce liquid shrinkage and prevent vaporization.

The casting methods of cast brass mainly include die casting, sand casting, centrifugal casting, continuous casting and investment casting. Different alloys need to be selected in a targeted manner.

Casting brass is a casting alloy based on Cu-Zn binary alloy. Its crystallization temperature interval is small and its casting performance is better. Compared with tin bronze, cast brass has higher mechanical properties. In addition, because brass contains a large amount of zinc, the cost is lower. These are the reasons why cast brass is widely used.

However, compared with tin bronze and aluminum bronze, cast brass has poor corrosion resistance. Due to the active chemical nature of zinc and the lower electrode potential, brass is more likely to be corroded. Especially in sea water and other corrosive media with electrolyte, the interphase current is generated between the copper-rich phase and the zinc-rich phase in the brass structure, which intensifies the corrosion of the zinc-rich phase with lower electrode potential, which is called dezincification corrosion.

The solid solubility of zinc in brass is very large. Under normal temperature equilibrium, about 37% of zinc can be dissolved in copper, while in actual production, about 30% of zinc can be dissolved in the as-cast state. Therefore, zinc has a good solid solution strengthening effect in copper. Although ordinary brass has certain strength, hardness and good casting process performance, it has poor wear resistance and corrosion resistance, especially against flowing sea water, steam and inorganic acid. Therefore, a small amount of other alloying elements (mainly Mn, Al, Fe, Si, Pb, etc.) are usually added to cast brass to improve its mechanical, physical and chemical properties, thereby forming special cast brass that can meet various performance requirements. , Such as free-cutting brass, navy brass, high-strength brass and die-cast brass.

The crystallization temperature range of brass is very small (about 30-40℃). When the zinc content increases, the liquidus temperature drops quickly and the melting point decreases accordingly. Therefore, brass has good fluidity and forms concentrated shrinkage cavities. , It is not easy to form porosity and intragranular segregation. Brass has a low melting point and contains a large amount of easy-to-evaporate element zinc. When it evaporates, it can prevent the alloy from getting gas and take away the gas in the copper liquid, so that there is less gas in the smelting process. Therefore, brass castings generally do not produce Stomata.

At the same time, when smelting brass, zinc itself has a strong deoxidizing effect, and no other deoxidizing agents are needed. Therefore, brass is easier to smelt than other copper alloys and has better casting properties. Due to the high affinity between zinc and oxygen, the oxide ZnO is easily formed during the brass smelting process, but unlike Al2O3, it is easily separated from the copper liquid into slag. As long as measures are taken to prevent secondary oxidation of the alloy, oxidation inclusion defects can generally be avoided . The shrinkage rate of brass is large, and concentrated shrinkage cavities are easily formed during solidification. Therefore, larger feeding risers can be set in accordance with the principle of sequential solidification. Brass has the characteristics of shell-like solidification and is less sensitive to casting cooling rate, so its mechanical properties are also less sensitive to changes in casting wall thickness.

Almost no binary brass is used in casting production. In order to meet special performance requirements and improve casting process performance, multiple brass casting parts are widely used

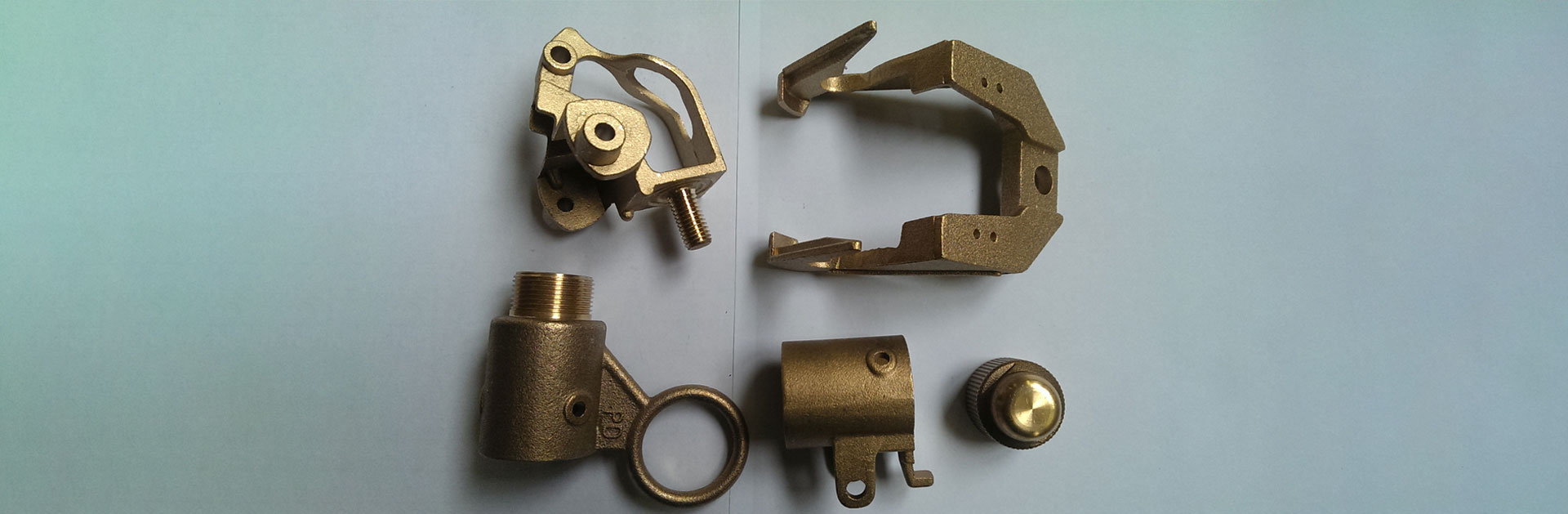

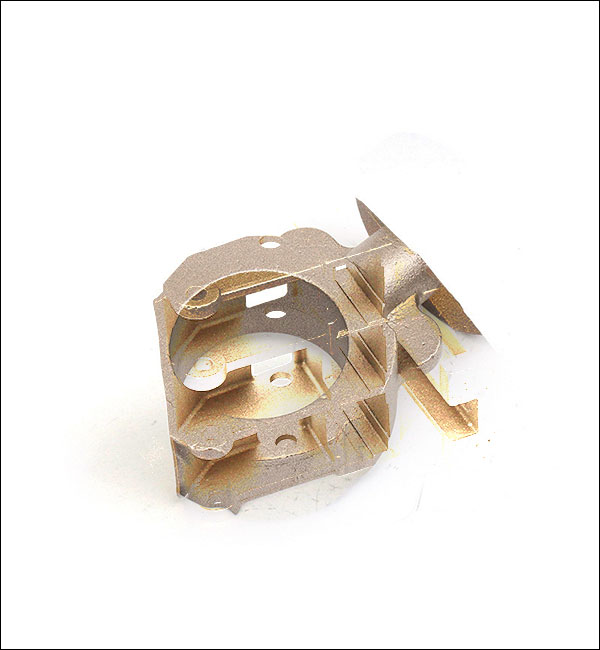

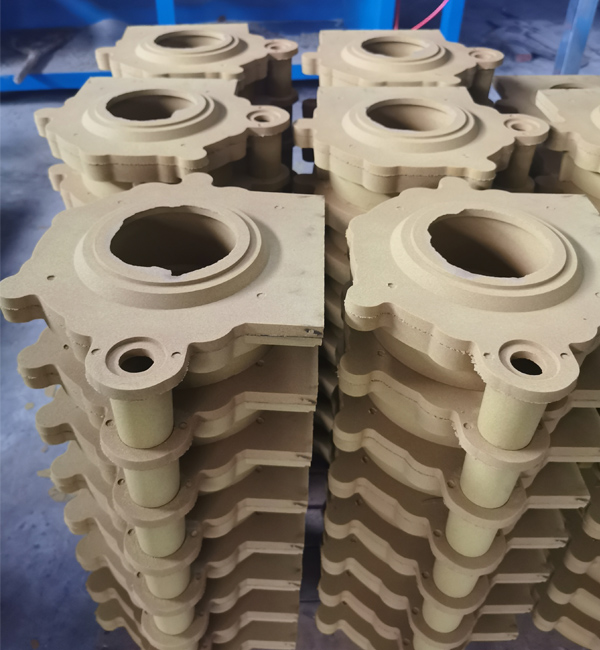

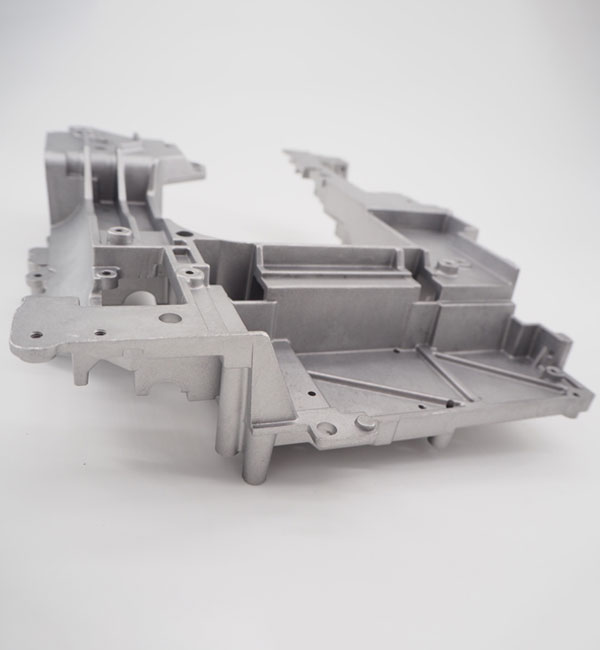

The Minghe Case Studies Of Brass Casting

Minghe Casting fabrication services are available for both design to reality and low to high volume production runs of your aluminum casting parts,zinc casting parts,magnesium casting,titanium casting parts,stainless steel casting parts,copper casting parts,steel casting parts, brass casting parts and more.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Brass Casting Supplier

Currently, our brass casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom brass casting fabrication service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your brass casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

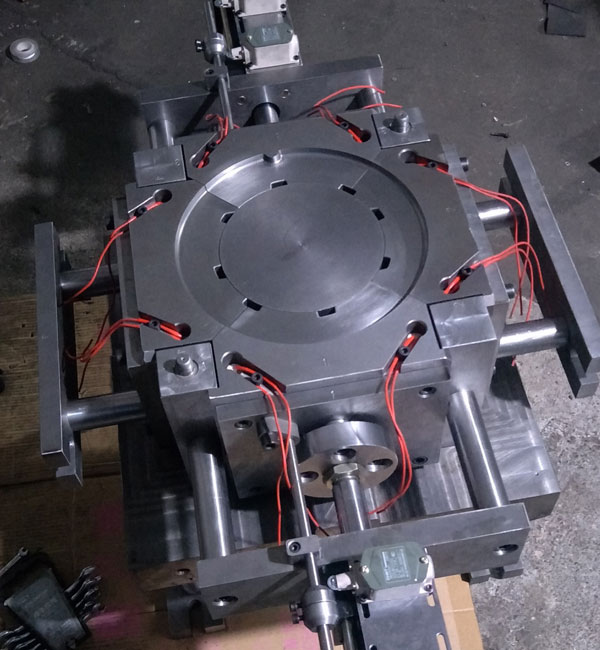

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.

Vacuum Casting

Vacuum Casting is a casting process in which metal is smelted, poured and crystallized in a vacuum chamber. Vacuum casting can minimize the gas content in the metal and prevent metal oxidation. This method can produce very demanding special alloy steel castings and extremely easily oxidized titanium alloy castings. Minghe Casting has a vacuum casting sub-factory, which is enough to solve all the problems related to vacuum casting