Bicycle Parts

Bicycle Parts Solutions By Casting &Cnc Machining

IATF 16949 CERTIFIED CAST MANUFACTURING AND CNC MACHINING FOR Bicycle Parts

Bicycle accessories is a collective term for all parts and accessories of the bicycle body. According to the large structural frame of the car body, it can be divided into several categories: frame, tire, pedal parts, front fork assembly, chain, flywheel, etc.

Among the 25 accessories of bicycle frame, tires, pedals, brakes and chains, none of its basic components are indispensable. Among them, the frame is the skeleton of the bicycle, and it bears the heaviest weight of people and goods. According to the working characteristics of each accessory, it can be roughly divided into guiding system, driving system and braking system.

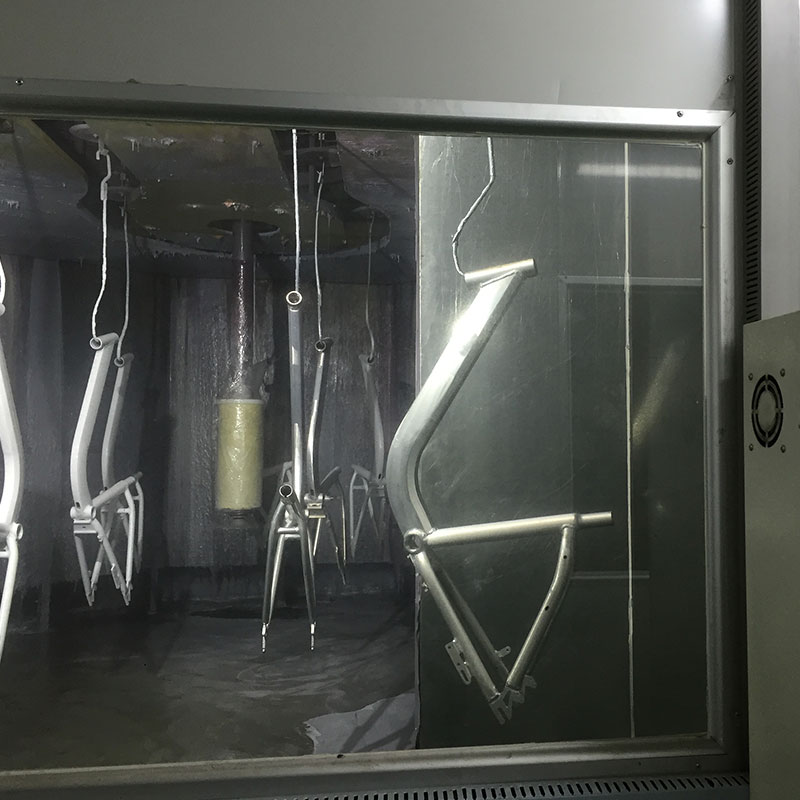

The frame components are the basic structure of the bicycle, as well as the skeleton and main body of the bicycle. Other components are also directly or indirectly installed on the frame. There are many structural forms of frame components, but the overall structure can be divided into two categories: men's frames and women's frames.

The frame is generally welded and assembled by ordinary carbon copper tubes. It is also formed by die-casting. In order to reduce the weight of the tube and increase the strength, higher-end bicycles are made of low-alloy steel tubes. In order to reduce the resistance of fast driving, some bicycles also use streamlined steel tubes.

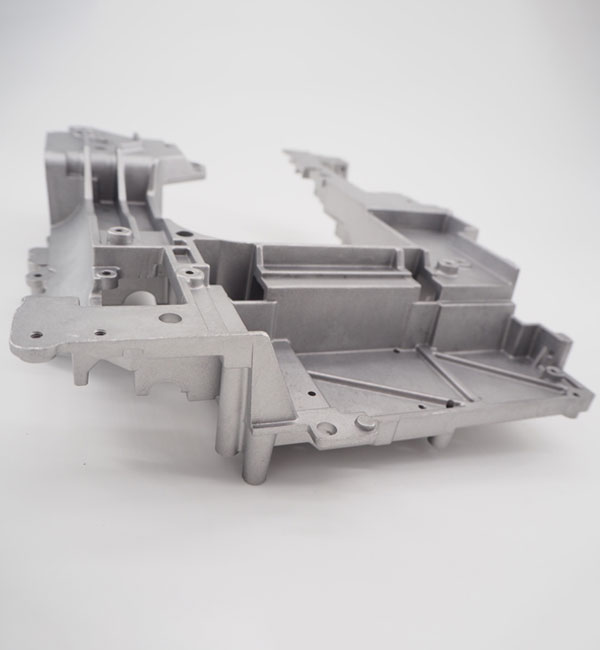

Minghe is a top China die casting parts manufacturer that understand the international quality system regulations and has the capabilities to deliver die casting bicycle parts and components products that are fully compliant. Based on the high Integrity complex die casting and rich experiences in mold manufacturing,cnc machining, and post treatment services, unmatched quality die casting parts for bicycle with high speed and high precision are offered here, a wide range of metal materials for selection to fabricate different products with certain specifications. Working with our bicycle die casting, affordable prices, high durability and fast delivery time and more benefits you can get.

Contact our Bicycle Parts engineer today to discuss the specifics of your complex projects.

1.Commonly Bicycle Parts Applications.

MINGHE’s experience is unrivaled in the design, development, and manufacture of precision die cast and cnc machining solutions for a wide range of Bicycle Parts applications, including but not limited to:

- Frame

- Tire

- Pedal parts

- Front fork assembly

- Chain

- Flywheel

- etc.,

2.Why Choose Us For Your Bicycle Parts Projects

Minghe has over 35 years of experience assisting parts casting manufacturers design cost-effective icycle components. When you partner with Minghe you can receive the following benefits from our die casting process:

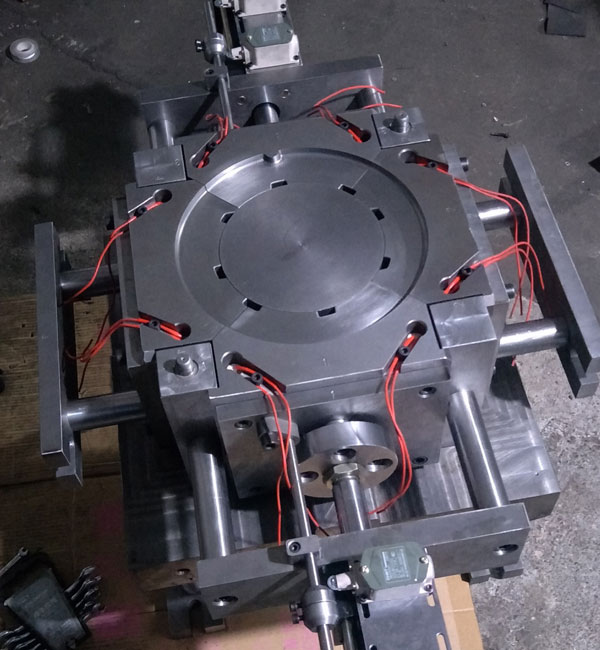

- Minghe’s die casting operation features 40 presses ranging from 250 to 3000 ton. We accommodate some of the most demanding bicycle parts runs in terms of volume, part size, and complexity. Because of our engineering and modeling capabilities, we are known by our clients as a company that can reduce part complexity, and make the manufacturing process more efficient.

- Minghe can help consolidate your supply chain by offering the complete package of die casting services in addition to engineering support, mold design and troubleshooting, machining, and logistics.

- Minghe is an ISO Certified Die Casting Manufacturer and has extensive experience in designing and manufacturing zinc and aluminum parts to Bicycle Parts quality specifications.

- With presses ranging from large to small, we have the capability to manufacture Bicycle Parts of all sizes, from a Frame to bicycle body structure for Bicycle Parts.

- We are ITAF 16949 certified and can provide part manufacturing for military and telecom applications.

- Our technology facilitates and streamlines production. Our suite of technology includes AutoCAD, Pro-E, MAGMAsoft®, CAD/CAM and EDI compatibility, and FARO Laser Scanning.

3.Other Manufacturing Service For Custom Bicycle Parts

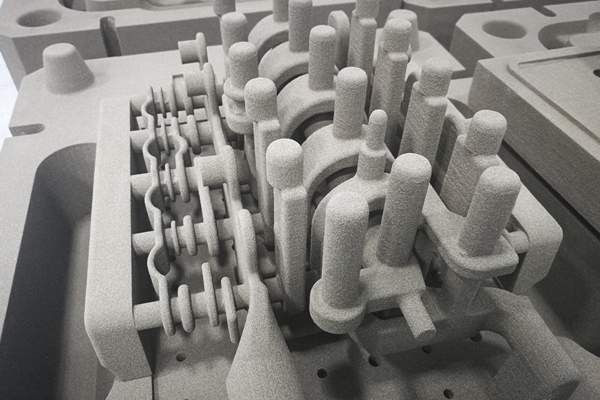

In addition, Minghe also provides CNC machining, investment casting, sand casting and other services related to customized Bicycle Parts.

| Cnc Machining Bicycle Parts |

| Investment Casting Bicycle Parts |

| Sand Casting Bicycle Parts |

4.Capabilities of Our Precision Manufacturing for Bicycle Parts

In addition, Minghe also provides CNC machining, investment casting, sand casting and other services related to customized Bicycle Parts.

AL360, AL380, AL383, and AL413, ZA-8, ZA-12, ZA-27,Aluminium A356,

Black, White, Silver, Red, Natural, Blue, Green and different colors as client requirements

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Die Casting,Mold Manufacturing,CNC milling, CNC turning, CNC drilling

Bike Frame;Bicycle Body Parts;

The Minghe Case Studies Of Bicycle Parts Casting

You have a complex part design, Minghe Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Minghe Casting ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Bicycle Parts Casting Service

Currently, our bicycle casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Custom china die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your bicycle casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

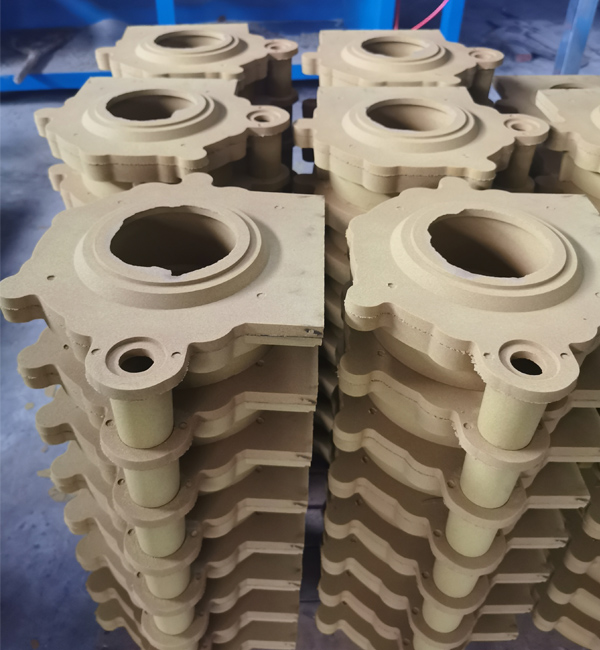

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.