Centrifugal Casting

What is Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; the cylindrical inner hole can be obtained without the core; it is helpful to eliminate the gas and inclusions in the liquid metal; it affects the metal The crystallization process improves the mechanical and physical properties of the casting.

According to the spatial position of the rotation axis of the mold, common centrifugal casting can be divided into horizontal centrifugal casting and vertical centrifugal casting. Centrifugal casting when the rotation axis of the mold is in a horizontal state or when the angle with the horizontal line is small (4°) is called horizontal centrifugal casting. Centrifugal casting when the rotation axis of the mold is in a vertical state is called vertical centrifugal casting. Centrifugal casting in which the rotation axis of the mold has a large angle with the horizontal and vertical lines is called inclined axis centrifugal casting, but it is rarely used.

The Application Field Of Centrifugal Casting

Castings with significant production benefits include:

- - Bimetal cast iron roll;

- - Heat-resistant steel roller table at the bottom of the heating furnace;

- - Special steel seamless steel pipe;

- - Brake drum, piston ring blank, copper alloy worm wheel;

- - Special-shaped castings such as impellers, metal dentures, gold and silver mesons, small valves and cast aluminum motor rotors.

Centrifugal casting was first used to produce cast pipes, and then this process has been rapidly developed. At home and abroad, the centrifugal casting process is used in metallurgy, mining, transportation, irrigation and drainage machinery, aviation, national defense, automobile and other industries to produce steel, iron and non-ferrous carbon alloy castings. Among them, the production of castings such as centrifugal cast iron pipes, internal combustion engine cylinder liners and shaft sleeves is the most common. For some forming tools and gear castings, centrifugal force pouring can also be used for the molten mold shell, which can not only improve the accuracy of the casting, but also improve the mechanical properties of the casting.

Castings with large production output include:

- - Iron pipe: Nearly 1/2 of the total annual output of ductile iron in the world is iron pipe produced by centrifugal casting

- - Cylinder liners of diesel engines and gasoline engines

- - Various types of steel sleeves and steel pipes

- - Bimetallic steel back copper sleeve, bearing bushes of various alloys

- - Paper machine drum

Founded in 1995, China Minghe Casting is an industry standard formulation unit for pattern forming molds for centrifugal casting. Minghe is located in the world's industrial capital-Dongguan, China. It is a high-tech enterprise in Guangdong Province. It has a production workshop with a construction area of 18,000 square meters. It is equipped with equipment for research and development, design, casting, machining, assembly, and surface treatment. It is the Dongguan R&D center and Technology Center. Minghe Casting now has 6 invention patents and 20 utility model patents. It is a trademark enterprise in Guangdong Province. The company has more than 230 employees, including 36 mold design engineers and 39 technicians; it has 40 CNC processing equipment and general processing equipment. 28 units, 3 coordinate measuring machines, and 1 reverse scanner. Using computer three-dimensional design, programming, computer-aided processing technology, using FM method to cast aluminum mold blanks, combined with Minghe Casting created TEFLON (TEFLON) surface coating technology and subsidiary Minghe Powder Coating Factory, so that mold quality, precision, efficiency, The service life can meet the requirements of customers. The company's technical staff guide the mold assembly, use, trial production, free maintenance, and can provide a full set of centrifugal casting technology according to customer needs.

The Features Of Centrifugal Casting

- – There is almost no metal consumption in the gating system and the riser system, which improves the production rate of the process;

- – The core is not used in the production of hollow castings, so the metal filling ability can be greatly improved when producing long tubular castings, the ratio of the wall thickness of the castings to the length or diameter can be reduced, and the production process of sleeve and tube castings can be simplified;

- – The casting has high density, few defects such as pores and slag inclusion, and high mechanical properties;

- – It is convenient to manufacture barrel and sleeve composite metal castings, such as steel-backed copper sleeves, bimetallic rolls, etc.; when forming castings, centrifugal motion can be used to increase the metal filling ability, so thin-walled castings can be produced.

- – There are certain limitations when used in the production of special-shaped castings.

- – The diameter of the inner hole of the casting is not accurate, the surface of the inner hole is relatively rough, the quality is poor, and the machining allowance is large;

- – Castings are prone to segregation of specific gravity, so they are not suitable for castings that are prone to segregation of specific gravity (such as lead bronze), and are especially not suitable for casting alloys with impurities larger than molten metal.

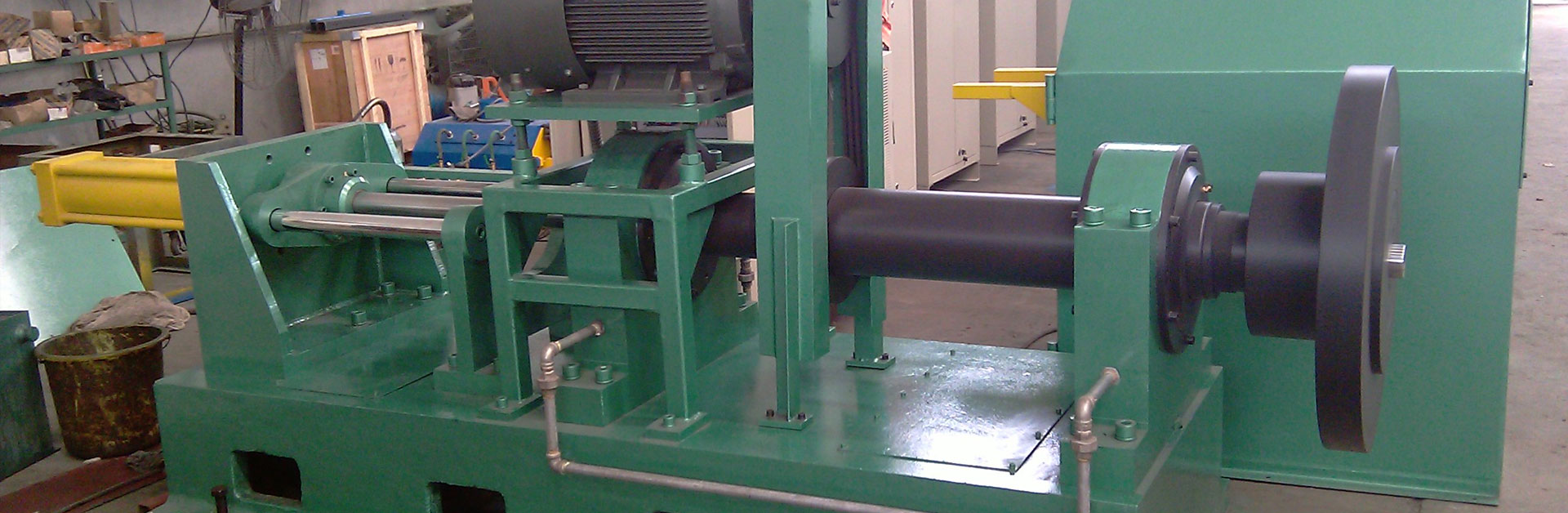

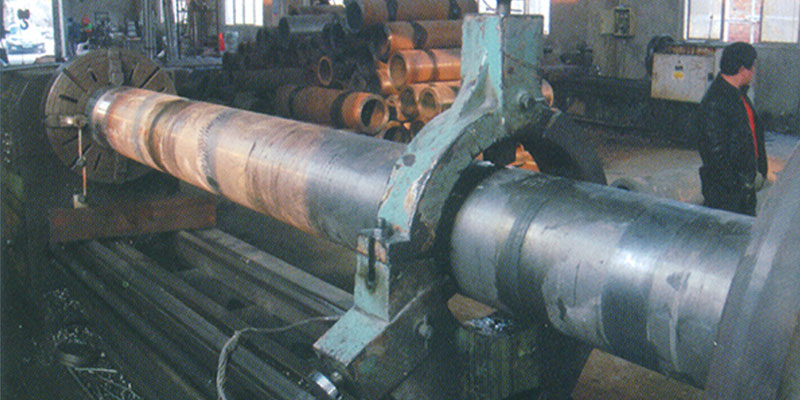

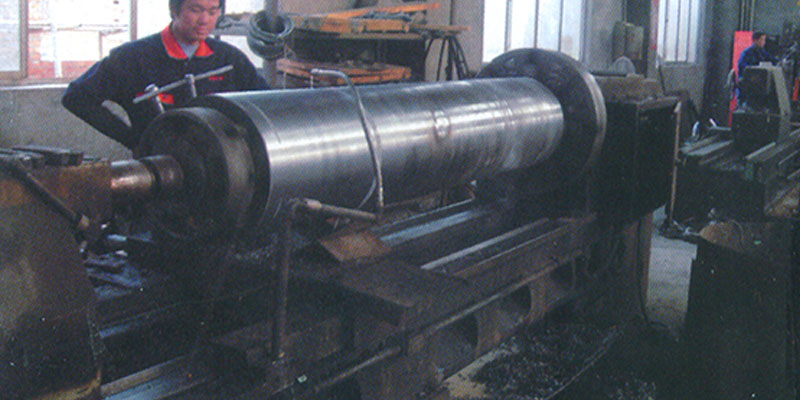

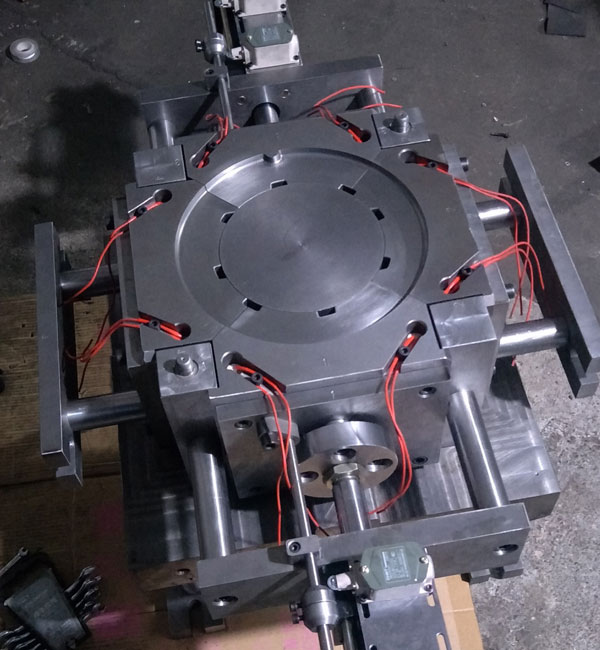

Different Types Production Scenario Of Centrifugal Casting

Minghe always adheres to the customer's requirements and the company's service standards. In any link of mold design, mold assembly, mold debugging, mold trial production, casting process, etc., there are dedicated engineers to keep you on the phone;

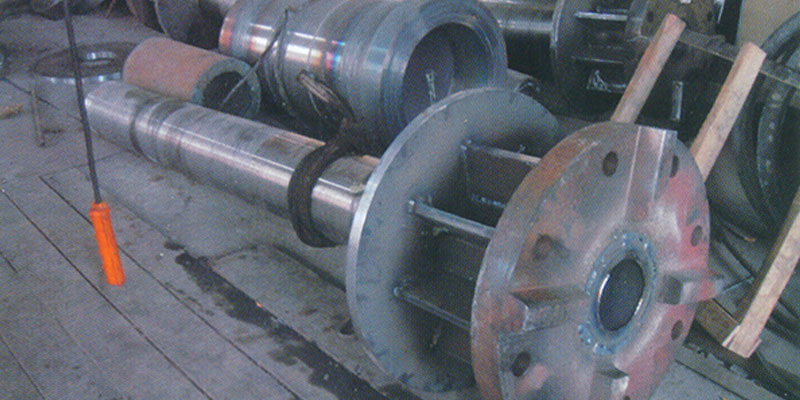

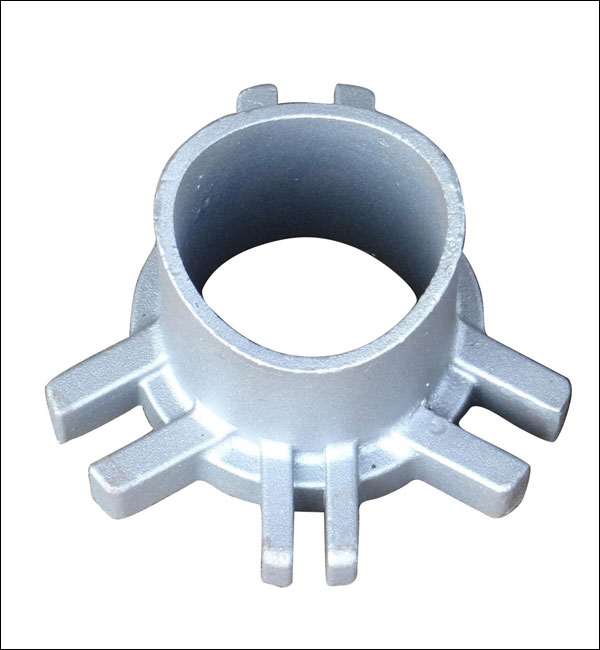

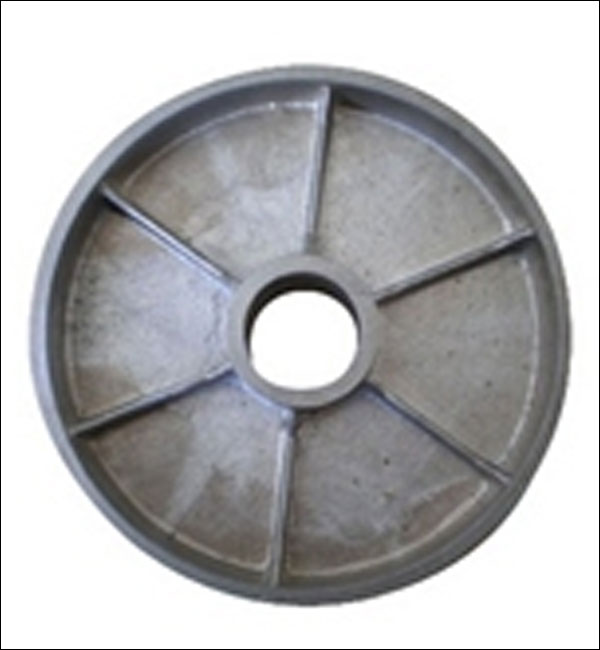

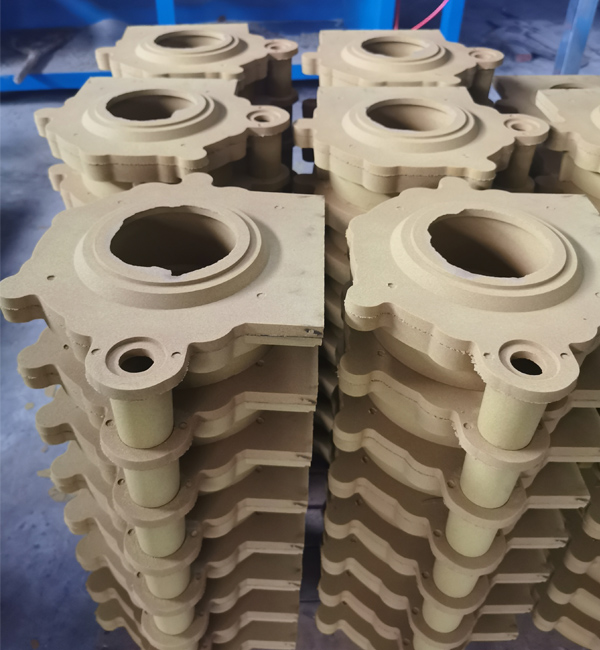

| The Scenario Of Manufacturing Centrifugal Casting1 ▶ |

| The Scenario Of ManufacturingCentrifugal Casting2 ▶ |

| The Scenario Of Manufacturing Centrifugal Casting3 ▶ |

| The Scenario Of Manufacturing Centrifugal Casting4▶ |

| The Scenario Of Manufacturing Centrifugal Casting5▶ |

| The Scenario Of Manufacturing Centrifugal Casting6▶ |

| The Scenario Of Manufacturing Centrifugal Casting7 ▶ |

| The Scenario Of Manufacturing Centrifugal Casting8▶ |

| The Scenario Of Manufacturing Centrifugal Casting9 ▶ |

| The Scenario Of Manufacturing Centrifugal Casting10▶ |

| The Scenario Of Manufacturing Centrifugal Casting11 ▶ |

| The Scenario Of Manufacturing Centrifugal Casting12▶ |

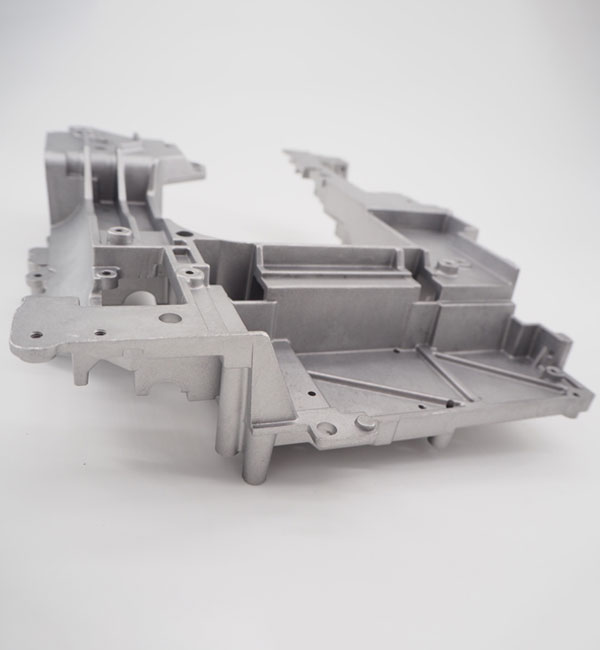

The Minghe Case Studies Of Centrifugal Casting

Minghe Casting fabrication services are available for both design to reality and low to high volume production runs of your die casting parts,sand casting parts,investment casting parts,metal casting parts, lost foam casting parts and more.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Centrifugal Casting Supplier

Currently, our centrifugal casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom centrifugal casting fabrication service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your centrifugal casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.