Post Processing

POST PROCESSING

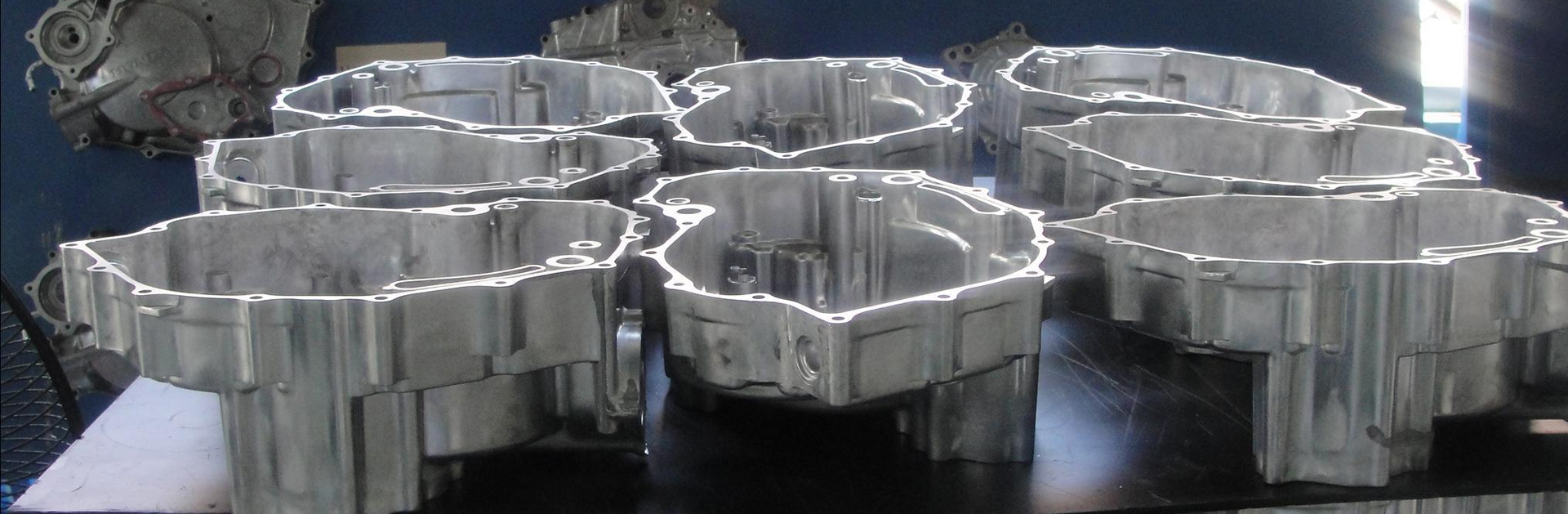

The die-casting post-treatment process includes cleaning of die-casting parts, metal surface treatment, quenching and tempering treatment and impregnation solution. The die castings cleaning work includes pouring system software, overflow system software, burrs and burrs removal, metal surface treatment of castings, and plastic and beauty solutions. The removal of die castings is more complicated, and the amount of labor is usually several times or even ten times that of aluminum die casting. Therefore, it is very necessary to maintain specialization and automation technology in the removal of die castings.

Removal Of Burrs/Pouring Burrs System Software/Overflow System Software

- The key to hand-made work is to use special tools such as mallets, needle-nose pliers, and frustrated knives to carry out hand-made removal work. The advantages are simplicity and convenience; the disadvantages are irregular wounds, easy damage to castings and deformation of castings. Hand-made work is not suitable for thick and medium-sized parts and complicated parts.

- The key to the work of mechanical equipment is to use industrial equipment such as trimming machine, CNC sawing machine, high-speed punching machine, four-column hydraulic press, friction press and other industrial equipment for bending work. The advantage is that the wound is neat and standard, not easy to damage the casting, and the work efficiency is high.

- The key to automation technology work is to use intelligent robots to automatically remove castings, remove the burrs and burrs of the pouring system software and the overflow system software, and maintain high efficiency and green manufacturing in the work of polishing and refurbishing.

Two Metal Surface Treatment

- The drum and vibration removal are suitable for general die castings

- The key effect of shot blasting and rust removal is to remove air scale, residue, burrs, etc. on the surface of castings

- The effect and basic principle of sand blasting removal and shot blasting rust removal are similar

- Grinding, grinding and polishing Choose grinding equipment, grinding and polishing machines and other raw materials, such as grinding stones, grinding paste, polishing fluid, and water, to grind or polish the surface of castings to remove residual marks after castings are removed. Or obtain smooth and consistent process performance.

Plastic Surgery Solution

- The thermal effect is heating the deformed die-casting to the annealing temperature, and then using professional effect grinding tools or tooling fixtures to carry out manual production or mechanical equipment correction.

- The cold effect is using special type effect grinding tools or tools, tooling fixtures to carry out manual production or mechanical equipment effect correction on deformed die castings at room temperature.

- Hardware polishing: hardware hand-made grinding hardware hand-made polishing and polishing Because of the characteristics of left and right, the post-treatment process of zinc alloy die castings has become an indispensable part of it.