Low Pressure Casting

What is Low Pressure Casting

Low pressure casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and compact structure. It is easy to cast large and thin-walled complex castings without risers, and the metal recovery rate can reach 95%. No pollution, easy to realize automation. However, the equipment cost is high and the production efficiency is low. Generally used for casting non-ferrous alloys.

Low-pressure casting is a casting method in which liquid alloy is pressed into the mold cavity from bottom to top under pressure, and solidified under pressure to obtain castings. The sealed crucible is filled with dry compressed air or inert gas. With the help of the pressure acting on the molten metal surface, the molten metal fills the mold smoothly along the riser pipe from bottom to top through the runner. The filling pressure is generally 20~60kPa. When the casting is completely solidified, the gas pressure on the liquid surface is released, so that the non-solidified molten metal in the riser pipe and the runner flows into the crucible by its own weight, then the mold is opened and the casting is taken out.

The production process of low pressure casting includes the following four basic procedures:

- - Metal smelting and preparation of molds or casting molds.

- - Preparations before pouring: including crucible sealing (fitting sealing cover), slag removal in riser pipe, measuring liquid level, sealing test, mold matching, tightening mold or mold, etc.

- - Pouring: including liquid lifting, filling, pressurization, solidification, pressure relief and cooling, etc.

- - Demoulding: including loose moulding and casting out.

The Application Of Low Pressure Casting

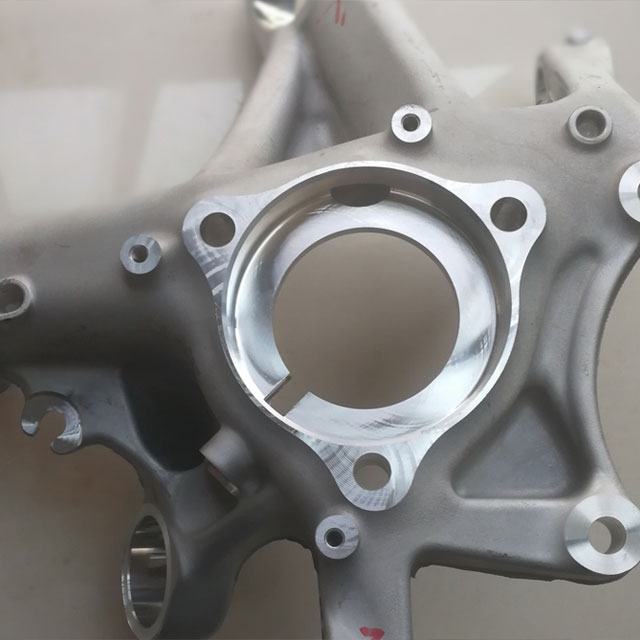

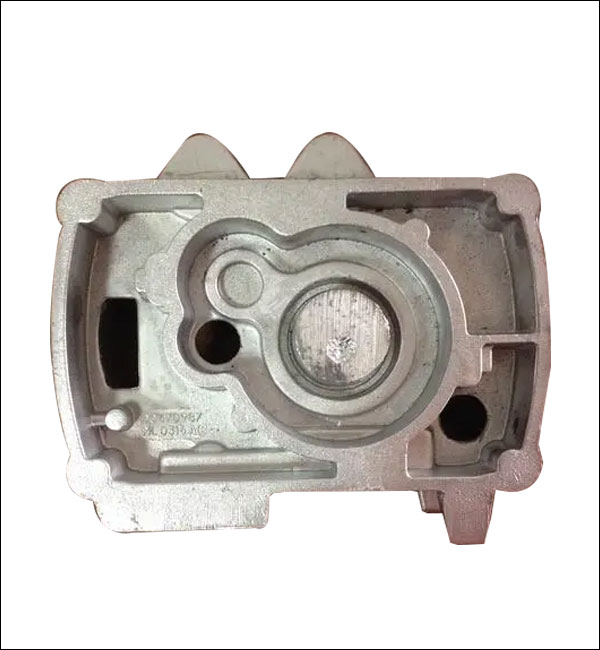

Low-pressure casting is the earliest anti-gravity casting technology, and it has been used in industrial production since the 1940s. Low pressure casting is ordinary die casting, and non-stressed parts can use this process. Nowadays, low-pressure casting is mainly used to produce aluminum alloy and magnesium alloy parts, such as automobile wheels in the automobile industry, cylinder blocks, cylinder heads, pistons, missile shells, impellers, wind guide wheels and other castings with complex shapes and high quality requirements in the automobile industry.When low-pressure casting is used to produce cast steel, such as cast steel wheels, the riser pipe needs to be made of special refractory materials. Low pressure casting can also be applied to small copper alloy castings, such as pipe fittings, cock taps in bathrooms, etc. The technology has been industrialized abroad.

The Features Of Low Pressure Casting

Low pressure casting can use sand, metal, graphite, etc. The filling process is different from gravity casting such as metal casting and sand casting, and it is also different from pressure casting with high pressure and high speed filling. It has the following advantages:

- - Filling with pure molten metal improves the purity of castings. Since the molten slag generally floats on the surface of the molten metal, the low-pressure casting is filled with the molten metal in the lower part of the crucible through the riser pipe, which completely avoids the possibility of the molten slag entering the mold cavity.

- - The liquid metal filling is stable, reducing or avoiding the tumbling, impact and splashing of the liquid metal during filling, thereby reducing the formation of oxidized slag.

- - The casting has good formability. The molten metal is filled under pressure, which can improve the fluidity of the molten metal, which is conducive to the formation of castings with clear contours and smooth surfaces, and is more beneficial for the formation of large thin-walled castings.

- - The casting crystallizes and solidifies under pressure, which can be fully fed and the casting structure is dense.

- - Improve the yield of molten metal. Under normal circumstances, there is no need for a riser, and the uncondensed metal in the riser pipe can be refluxed to the crucible for repeated use, which greatly improves the yield of molten metal. Generally up to 90%,

- - Convenient production and operation, good working conditions, high production efficiency, easy to realize mechanization and automation,

- - Low pressure casting also has some shortcomings, equipment and mold investment is relatively large; in the production of aluminum alloy castings, the crucible and riser pipe are in contact with the molten metal for a long time, which is susceptible to corrosion and scrap, which will also cause the molten metal to increase iron and deteriorate the performance.

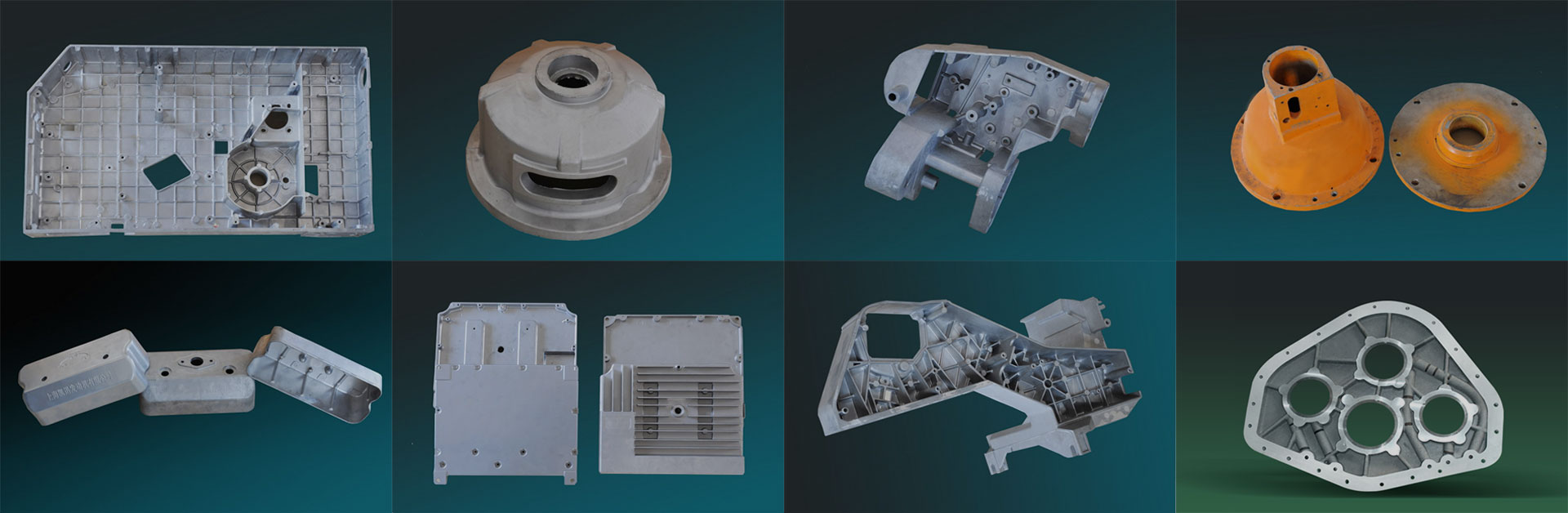

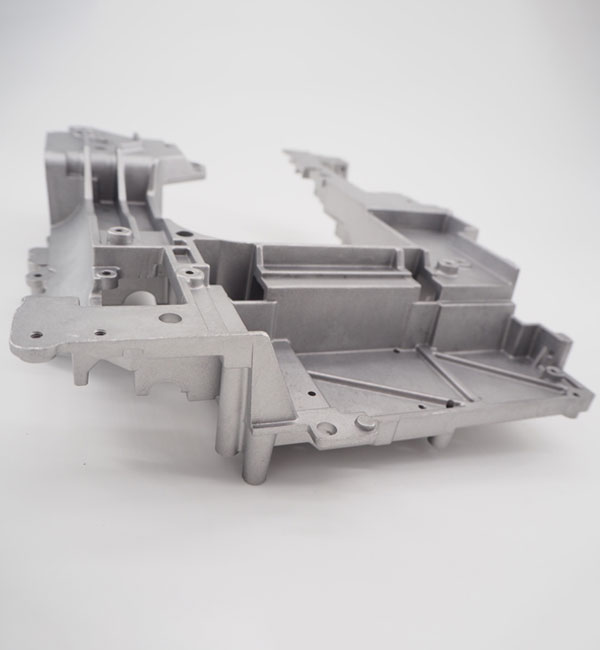

Different Types Production Scenario Of Low Pressure Casting

Minghe always adheres to the customer's requirements and the company's service standards. In any link of mold design, mold assembly, mold debugging, mold trial production, casting process, etc., there are dedicated engineers to keep you on the phone;

| Low Pressure Castings Shop 1 ▶ |

| Low Pressure Castings Shop 2 ▶ |

| Low Pressure Castings Shop 3 ▶ |

| Low Pressure Castings Shop 4▶ |

| Low Pressure Castings Shop 5▶ |

| Multifunctional drilling and tapping machine▶ |

| Aluminum alloy products quenching-tempering equipment ▶ |

| De-gate hydraulic press▶ |

| Furnace▶ |

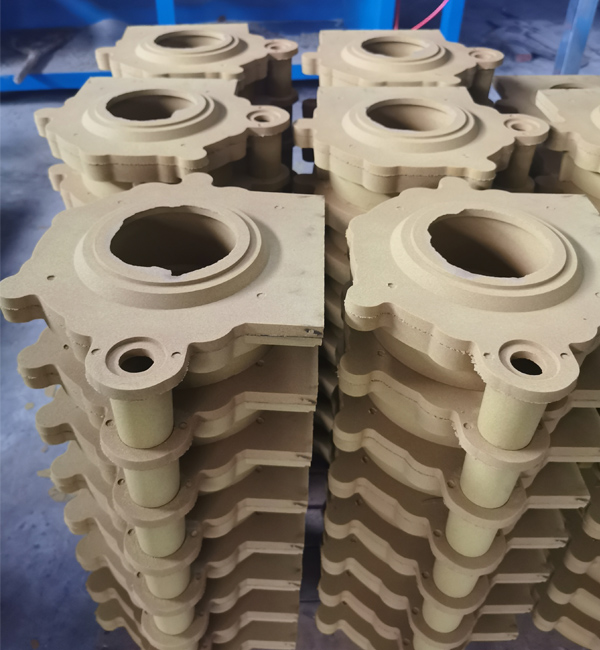

| Low pressure pouring equipment-core shell machine▶ |

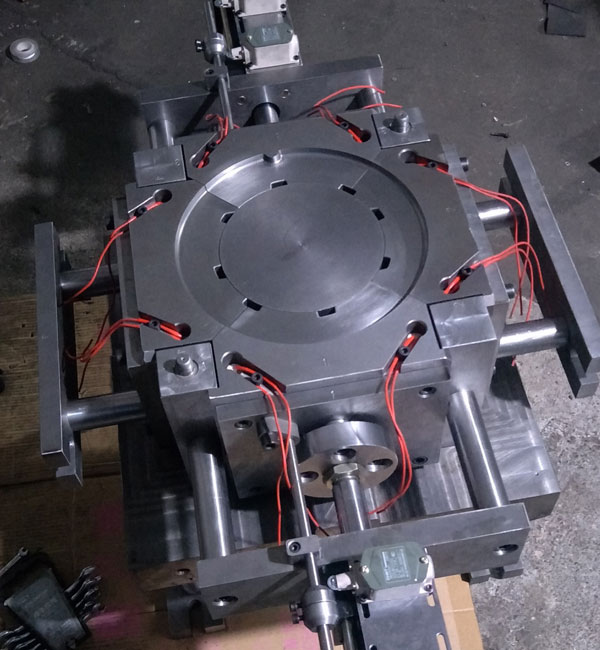

| Low pressure pouring machine▶ |

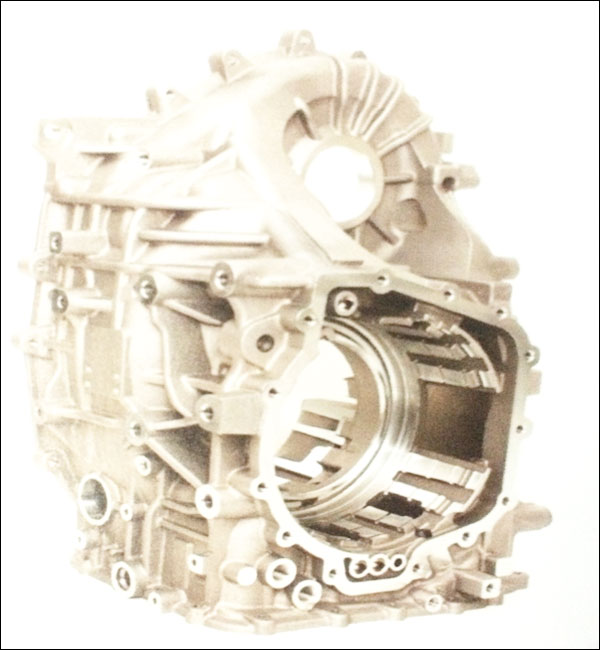

| Low-pressure casting product-gearbox body▶ |

The Minghe Case Studies Of Low Pressure Casting

Minghe Casting fabrication services are available for both design to reality and low to high volume production runs of your die casting parts,sand casting parts,investment casting parts,metal casting parts, lost foam casting parts and more.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Low Pressure Casting Supplier

Currently, our low pressure casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom low pressure casting fabrication service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your low pressure casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.