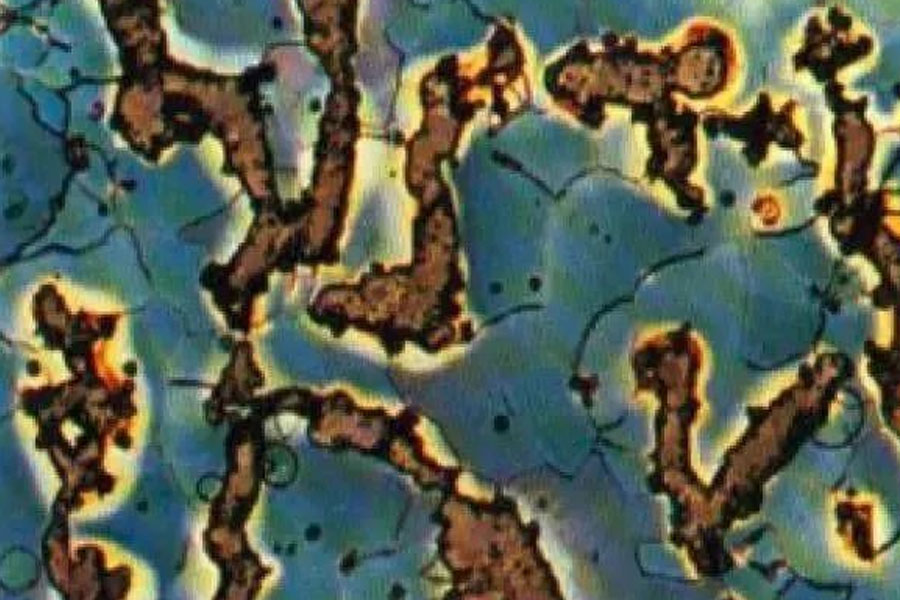

The Precautions For Ferritic Stainless Steel Continuous Casting

Compared with austenitic stainless steel, ferritic stainless steel has a higher yield strength. Under the same working conditions, materials with smaller cross-sections can be used to save costs; in addition, ferritic stainless steel does not contain Ni (special ones contain only a small amount) ), ...