The Method For Repairing Casting Defects

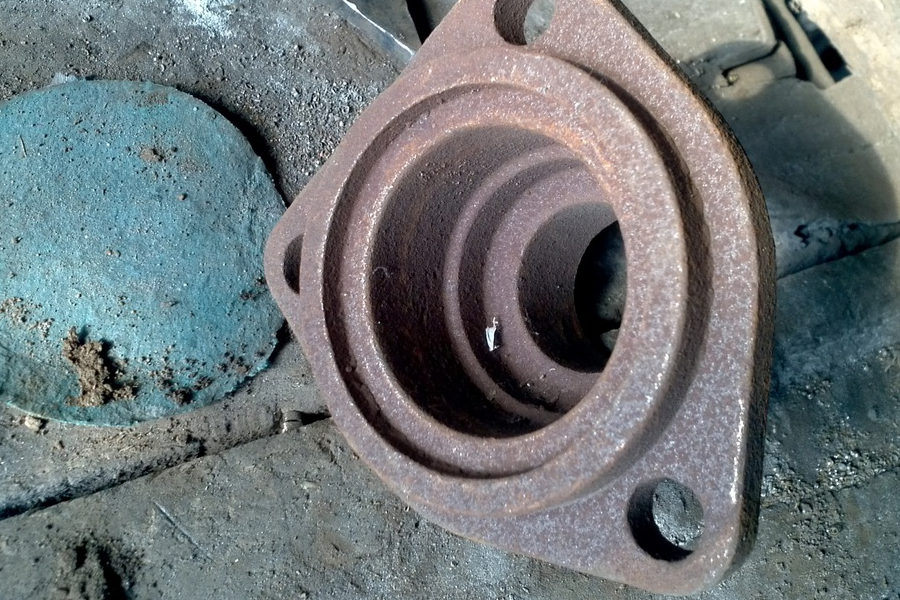

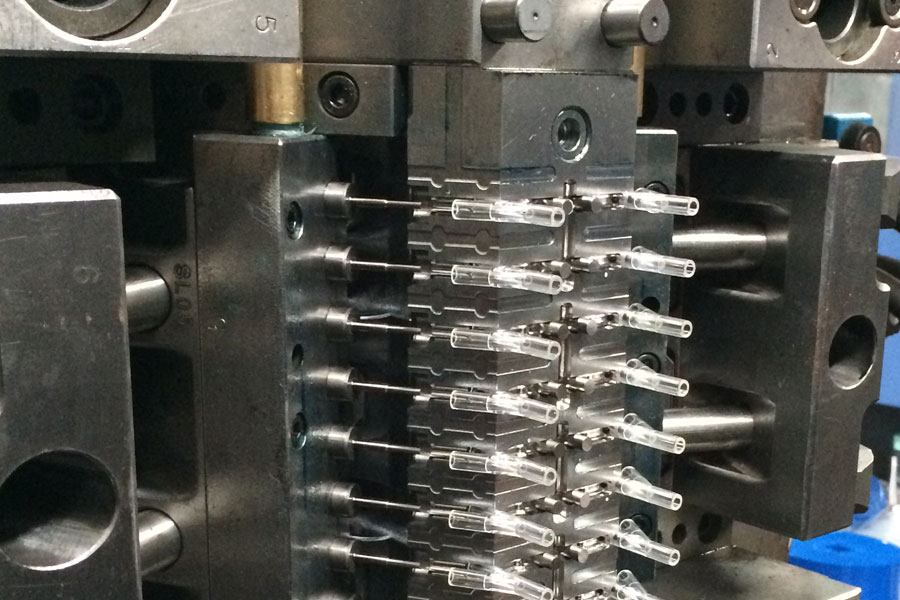

Repair situation and equipment analysis Caster glue: simple, extensive castings, generally repairing does not require subsequent processing, and there is no special strength and hardness requirements. The added value of this type of casting is relatively low. ...