The Rapid Manufacturing Of Complex Castings

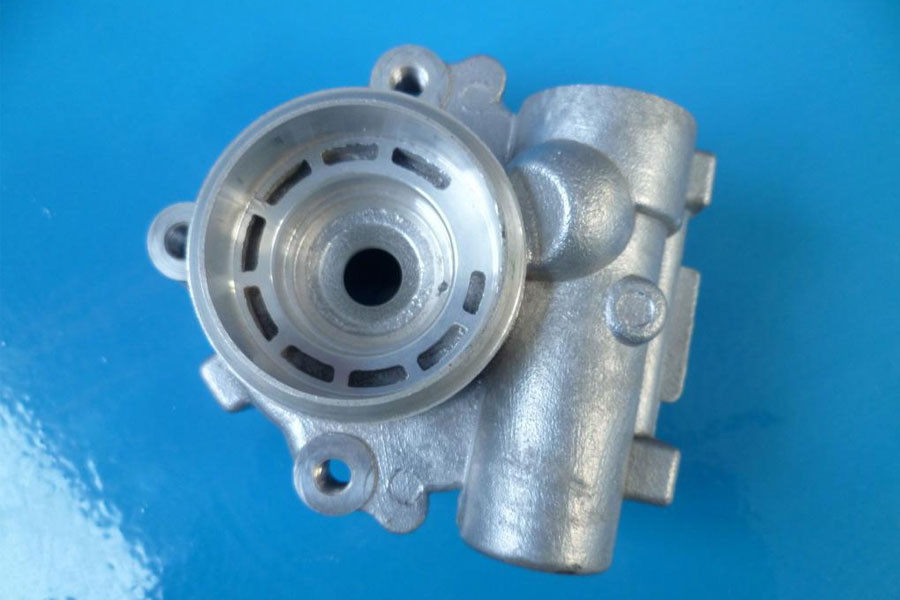

Because for complex castings, especially for thin-walled castings with complex shapes and produced in small batches, casting has always been a problem. What's more, customers now have high requirements for short cycle and low cost, and traditional craftsmanship is difficult to handle. ...