The Types Of Metallic Materials Failure

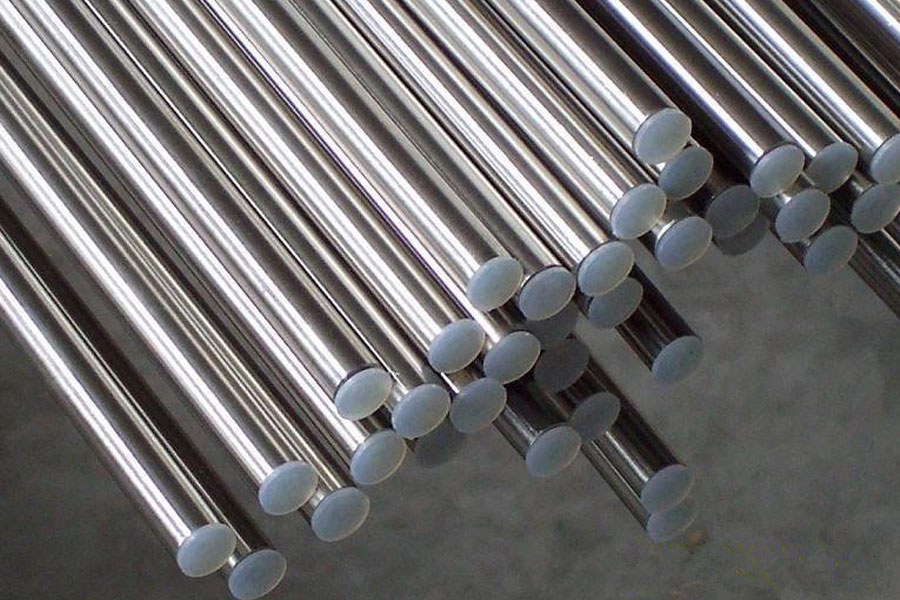

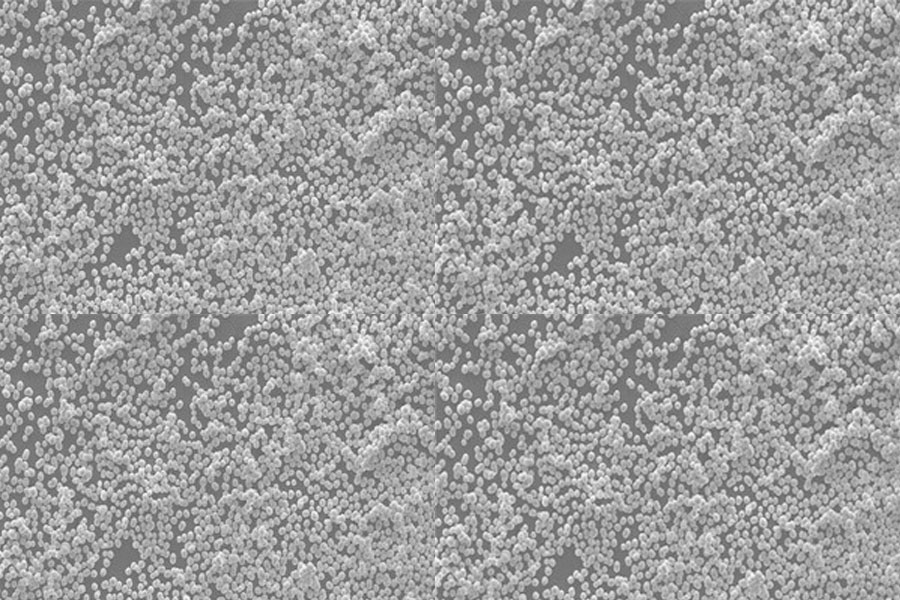

In recent years, as metal materials have become more and more widely used in various fields of production and life, the problem of material failure has become increasingly prominent. Material failure mainly refers to the inability of the mechanical component to complete its intended function due to ...