How To Calculate Pressure Die Casting Tonnage

Calculation Formula

The calculation formula for the selection of die-casting machine: Die-casting machine clamping force (t) = 1.4 * casting projected area * ratio of the projected area of the die casting-the orthographic projected area of the die casting * modulus (CM2).

The tonnage of the die-casting machine is indicated by the clamping force of the machine.

Since the die-casting alloy is punched in the "high-speed and high-pressure" state, if the die-casting machine is not tightly locked, serious material flying will occur, causing hidden dangers of work injury, messy site and poor quality of castings.

The calculation formula for the selection of die-casting machine for die-casting parts is as follows:

- Die-casting machine clamping force (t)=1.4*casting projected area*specific pressure

- Casting projected area-orthographic projected area of die casting * modulus (CM2)

If you select the die-casting machine separately in terms of weight or size

You can do this:

Size: Generally the casting area of the product (including the pouring system), the unit is calculated in cm, divided by 2.5, and the figure obtained is the minimum tonnage requirement.

Weight: It is necessary to know the maximum pouring volume of the machine. Many machine parameters are different from the actual machine configuration of the material pipe and the soup machine. For example, the theoretical pouring volume of 1250 tons is 13-25.4kg. In fact, many die-casting machines only have the maximum pouring volume of 10-12kg; the factory parameter of 1600 tons is 17-32kg pouring volume, which is actually about 16-20kg (depending on each Factory configuration).

The tonnage of the die-casting machine is the clamping force of the die-casting machine, not the clamping force. The clamping force of the die-casting machine is realized by the clamping force of the clamping cylinder and the toggle force expansion mechanism, not the force of the clamping cylinder. As for the tonnage of the die-casting machine, it is related to the total projected area of the die-casting part (including the projected area of the die-casting part, slag bag, cross runner, sprue and cake), it is best to calculate the accurate projected area instead of using coefficient. Because the product coefficient of large parts cannot be too high, and the product coefficient of small parts is higher, it is more accurate to calculate the clamping force based on the actual projected area of the mold. As for the choice of casting pressure, it depends on the complexity of the casting, generally ranging from 500bar to 800bar.

Since the die-casting alloy is punched in the "high-speed and high-pressure" state, if the die-casting machine is not tightly locked, serious material flying will occur, causing hidden dangers of work injury, messy site and poor quality of castings.

Therefore, the die-casting machine can provide 160t mold force, and the die-casting machine is called 160t.

Actual Operation Of Calculate Pressure Die Casting Tonnage

My product is xx grams and the size is xx*xx mm. What size of machine should I use to print it? "——This is a common problem in the selection of die-casting die-casting machines.

The selection of die casting machine roughly includes three aspects:

- 1. The tonnage of the die-casting machine is related to whether the material will fly

- 2. Mold size, which is related to whether the mold can be installed on the die casting machine

Pouring amount, which is related to whether the product can be shaped

How to calculate product machine tonnage?

Regarding the problem of calculating the tonnage of a die-casting machine, it is difficult to say that it is not difficult, but it is not easy to say it is simple. As long as you understand the relationship, it is easy to calculate the machine tonnage required for the product.

First determine such a concept

The tonnage of the die-casting machine refers to the clamping force of the die-casting machine

Clamping force is the first parameter to be determined when selecting a die casting machine. The role of the clamping force is mainly to overcome the bulging force in the cavity, to lock the mold, prevent the molten metal from splashing, and ensure the dimensional accuracy of the casting.

So back to the original question, how to calculate the clamping force of the die casting machine? First look at the following formula:

Die-casting machine clamping force>mold opening force F1×1.1

So, what is the mold opening force and how to calculate it?

Mold opening force refers to the force acting on the cavity to make the mold expand during die casting production. The mold opening force can be obtained by the following formula:

Casting area × casting pressure

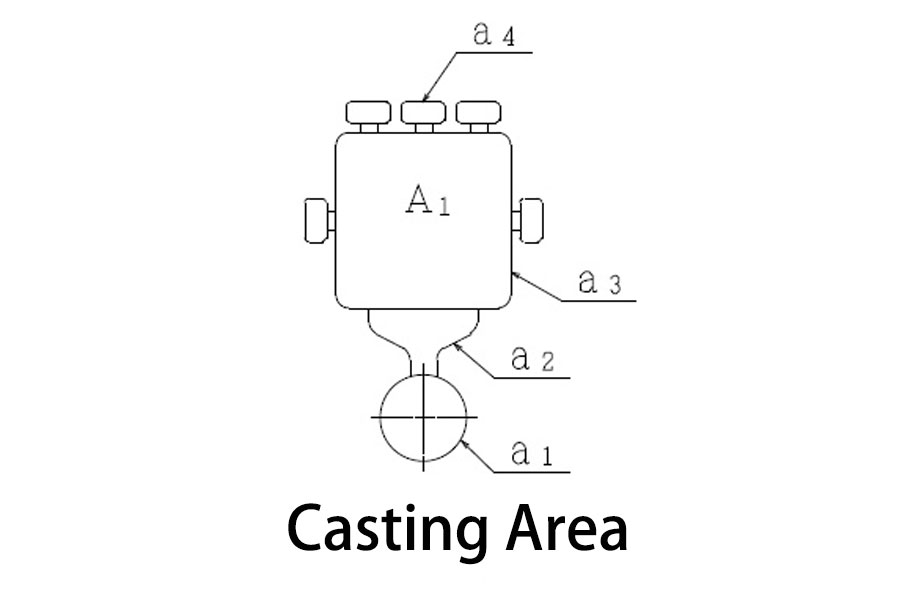

Casting area A1=a1+a2+a3+a4=cake area + runner area + product area + slag bag area

Area estimation When the mold is not fully designed, we only know the projected area a3 of the product, and estimate it

- a2=0.21a3

- a4=0.12a3

The area of the cake is based on the punch

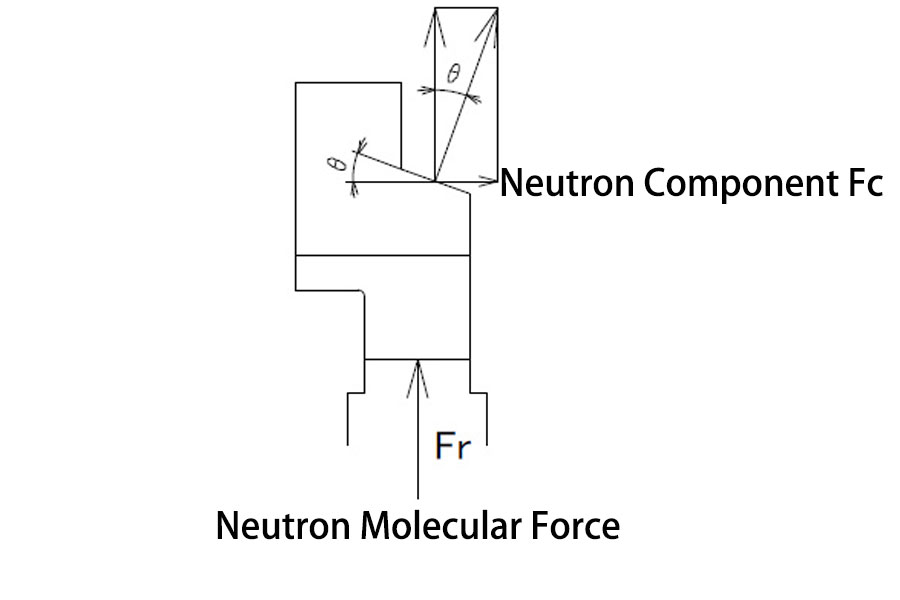

Mold opening force F1=casting pressure Pp×casting area A1+neutron component force Fc (calculation of mold opening force with slider)

When there are slider neutrons, neutron molecules need to be calculated

Neutron return force Fr=product area Ac×calculated casting pressure×75%

Neutron component force Fc=neutron return force Fr×tanθ

Mold opening force F1=(a1+a2)×Pp+a3×Pp×0.75+a4×Pp×0.25+Fc

Casting pressure distribution:

Because the temperature of the mold is not suitable and the pressure transmission is not uniform, the pressure applied to each part is classified and calculated as follows:

- Product department=calculated casting pressure×75%

- Slag bag section = calculated casting pressure × 25%

- Cake, runner part = calculated casting pressure × 100%

Casting pressure estimation:

Aluminum: The air tightness requirement is generally above 80MPa, other 60MPa

Zinc: about 30MPa

The clamping force needs to be 1.1 times or more of the mold opening force. If the mold opening force is greater than the clamping force, flashing (short shot) and oversize are likely to occur, and actual production cannot be carried out.

In summary, the final calculation formula of die casting machine tonnage can be obtained:

Clamping force> mold opening force × 1.1 = casting area × casting pressure = (cake area + runner area + product area + slag bag area) × casting pressure × 1.1

Die casting machine tonnage = clamping force/10, clamping force unit is KN

Please keep the source and address of this article for reprinting: How To Calculate Pressure Die Casting Tonnage

Minghe Casting Company are dedicated to manufacture and provide quality and high performance Casting Parts(metal die casting parts range mainly include Thin-Wall Die Casting,Hot Chamber Die Casting,Cold Chamber Die Casting),Round Service(Die Casting Service,Cnc Machining,Mold Making,Surface Treatment).Any custom Aluminum die casting, magnesium or Zamak/zinc die casting and other castings requirements are welcome to contact us.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machines, and other facilities, ranging from blasters to Ultra Sonic washing machines.Minghe not only has advanced equipment but also have professional team of experienced engineers,operators and inspectors to make the customer’s design come true.

Contract manufacturer of die castings. Capabilities include cold chamber aluminum die casting parts from 0.15 lbs. to 6 lbs., quick change set up, and machining. Value-added services include polishing, vibrating, deburring, shot blasting, painting, plating, coating, assembly, and tooling. Materials worked with include alloys such as 360, 380, 383, and 413.

Zinc die casting design assistance/concurrent engineering services. Custom manufacturer of precision zinc die castings. Miniature castings, high pressure die castings, multi-slide mold castings, conventional mold castings, unit die and independent die castings and cavity sealed castings can be manufactured. Castings can be manufactured in lengths and widths up to 24 in. in +/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast magnesium, Capabilities include high-pressure magnesium die casting up to 200 ton hot chamber & 3000 ton cold chamber, tooling design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.

ITAF16949 certified. Additional Casting Service Include investment casting,sand casting,Gravity Casting, Lost Foam Casting,Centrifugal Casting,Vacuum Casting,Permanent Mold Casting,.Capabilities include EDI, engineering assistance, solid modeling and secondary processing.

Casting Industries Parts Case Studies for: Cars, Bikes, Aircraft, Musical instruments, Watercraft, Optical devices, Sensors, Models, Electronic devices, Enclosures, Clocks, Machinery, Engines, Furniture, Jewelry, Jigs, Telecom, Lighting, Medical devices, Photographic devices, Robots, Sculptures, Sound equipment, Sporting equipment, Tooling, Toys and more.

What Can we help you do next?

∇ Go To Homepage For Die Casting China

→Casting Parts-Find out what we have done.

→Ralated Tips About Die Casting Services

By Minghe Die Casting Manufacturer |Categories: Helpful Articles |Material Tags: Aluminum Casting, Zinc Casting, Magnesium Casting, Titanium Casting, Stainless Steel Casting, Brass Casting,Bronze Casting,Casting Video,Company History,Aluminum Die Casting |Comments Off