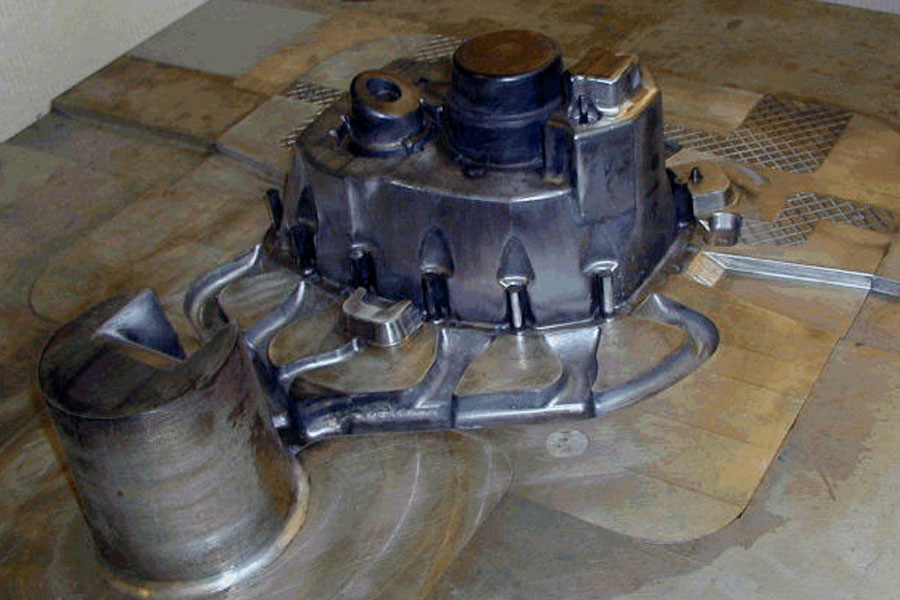

Ten Kinds Casting Processes In Foundries

This article summarizes ten casting processes and provides detailed explanations of these processes.Including Sand casting, Investment casting,Die casting,Low pressure casting,Centrifugal casting ,Gravity Die Casting,Vacuum casting,Squeeze casting,Lost foam casting and Continuous casting. ...