The Advantages Of AlSi10MgMn Alloy Die Casting

In recent years, my country's automobile industry has achieved rapid development. With the increasing concern of environmental protection issues, energy-saving and emission-reduction technologies focusing on lightweighting have become one of the common issues in the automotive industry. As the material of choice for lightweight technology, aluminum alloy has been widely used in the automotive industry.

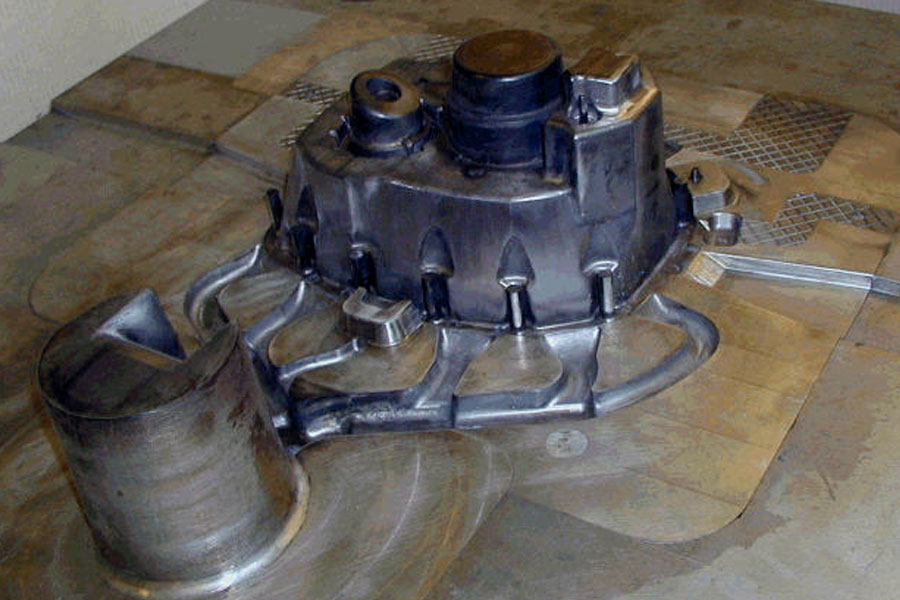

Die casting is one of the main forming methods of cast aluminum alloy. It has the characteristics of high material utilization, good surface forming quality and excellent mechanical properties. It occupies an important position in the production of aluminum alloy auto parts. Die-casting AlSi10MgMn alloy is Al-Si-Mg-Mn series high-strength and toughness aluminum alloy with good casting performance. Die-casting parts, especially high-vacuum die-casting parts, have excellent mechanical properties, and can be further strengthened by heat treatment. Therefore, this type of alloy has a thin wall and structure It has broad application prospects in the production of complex and load-bearing automobile structural parts or security parts.

Based on the self-developed high-vacuum die-casting technology, this paper studies the influence of mold cavity vacuum on the structure and performance of castings when molten metal is filled; the high-vacuum die-casting technology is used to study the effects of artificial aging T1, high temperature solution treatment T5, and T6 respectively.

Optimization of the structure and properties of high-vacuum die-casting AlSi10MgMn; according to actual production needs, the influence of Mg content on the structure and properties of low-vacuum (ordinary) die-casting AlSi10MgMn was studied. Research indicates:

- High vacuum die casting can significantly reduce the gas content of castings and increase the density of castings. Compared with ordinary die-casting, the toughness index of high-vacuum die-casting has increased by 55.1%, and the tensile strength, yield strength, elongation, and hardness of the material have increased by 12.7%, 38.4%, 130.4%, and 4.9%, respectively.

- Artificial aging can significantly improve the performance of high-vacuum die-casting AlSi10MgMn castings, especially the strength. The ageing temperature is 170 ℃, the ageing time is 8h, the tensile strength of the material reaches 351.3MPa, and the yield strength reaches 248.9MPa, which are respectively increased by 13% and 30.5% compared to the castings in the as-cast state.

- T5 high temperature heat treatment can improve the structure of the casting, and the strength and elongation of the casting have been greatly improved, especially the elongation. When the solution temperature is 510℃, the solution time is 3h, the aging temperature is 155℃, and the aging time is 2h, the elongation of the casting after heat treatment can reach 9.2%, and the toughness index can reach 1163.9. After solution treatment, the microstructure of the casting changes, and the eutectic silicon undergoes melting, granulation and spheroidization, and is evenly distributed on the α-Al solid solution.

- Through orthogonal experiments, the influence of various process factors of T6 on the properties of castings is studied. When the solution temperature is 500℃, the solution time is 2h, the aging temperature is 170℃, and the aging time is 4h, the tensile strength of the material is The strength can reach 358.4MPa, the yield strength reaches 286.6 MPa, the elongation rate reaches 6.1%, the Brinell hardness is 110.4, and the toughness index reaches 1103.8.

- Low vacuum die casting can reduce the gas content inside the casting. During high temperature and short-time solution treatment, no bubbling occurs on the surface of the casting, and the size remains stable. High temperature and short time heat treatment can improve the internal structure of the casting, increase the elongation of the casting and improve the strength and toughness of the casting. For castings that do not require heat treatment, control the Mg content to 0.4% to 0.65%; for castings that require artificial aging, when the Mg content is 0.2% to 0.4%, higher strength and toughness can be obtained. For ordinary die castings, when the Mg content is 0.06%, the castings can obtain better strength and toughness in the as-cast state or after artificial aging.

Please keep the source and address of this article for reprinting: The Advantages Of AlSi10MgMn Alloy Die Casting

Minghe Die Casting Company are dedicated to manufacture and provide quality and high performance Casting Parts(metal die casting parts range mainly include Thin-Wall Die Casting,Hot Chamber Die Casting,Cold Chamber Die Casting),Round Service(Die Casting Service,Cnc Machining,Mold Making,Surface Treatment).Any custom Aluminum die casting, magnesium or Zamak/zinc die casting and other castings requirements are welcome to contact us.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machines, and other facilities, ranging from blasters to Ultra Sonic washing machines.Minghe not only has advanced equipment but also have professional team of experienced engineers,operators and inspectors to make the customer’s design come true.

Contract manufacturer of die castings. Capabilities include cold chamber aluminum die casting parts from 0.15 lbs. to 6 lbs., quick change set up, and machining. Value-added services include polishing, vibrating, deburring, shot blasting, painting, plating, coating, assembly, and tooling. Materials worked with include alloys such as 360, 380, 383, and 413.

Zinc die casting design assistance/concurrent engineering services. Custom manufacturer of precision zinc die castings. Miniature castings, high pressure die castings, multi-slide mold castings, conventional mold castings, unit die and independent die castings and cavity sealed castings can be manufactured. Castings can be manufactured in lengths and widths up to 24 in. in +/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast magnesium, Capabilities include high-pressure magnesium die casting up to 200 ton hot chamber & 3000 ton cold chamber, tooling design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.

ITAF16949 certified. Additional Casting Service Include investment casting,sand casting,Gravity Casting, Lost Foam Casting,Centrifugal Casting,Vacuum Casting,Permanent Mold Casting,.Capabilities include EDI, engineering assistance, solid modeling and secondary processing.

Casting Industries Parts Case Studies for: Cars, Bikes, Aircraft, Musical instruments, Watercraft, Optical devices, Sensors, Models, Electronic devices, Enclosures, Clocks, Machinery, Engines, Furniture, Jewelry, Jigs, Telecom, Lighting, Medical devices, Photographic devices, Robots, Sculptures, Sound equipment, Sporting equipment, Tooling, Toys and more.

What Can we help you do next?

∇ Go To Homepage For Die Casting China

→Casting Parts-Find out what we have done.

→Ralated Tips About Die Casting Services

By Minghe Die Casting Manufacturer |Categories: Helpful Articles |Material Tags: Aluminum Casting, Zinc Casting, Magnesium Casting, Titanium Casting, Stainless Steel Casting, Brass Casting,Bronze Casting,Casting Video,Company History,Aluminum Die Casting |Comments Off