The Ways To Solve The Special Problems Of Large Ductile Iron Castings

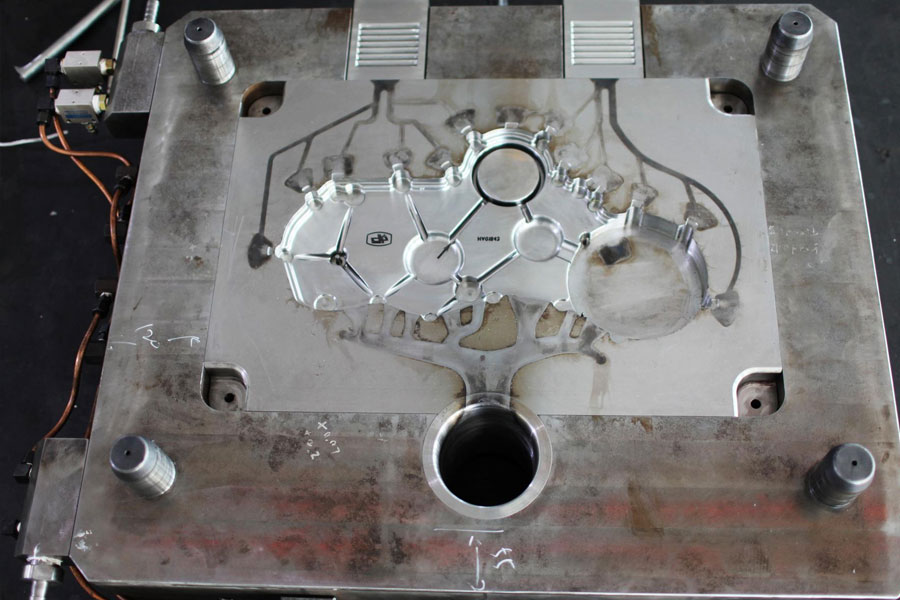

There are many types of large ductile iron parts, such as: large diesel engine block, large wheel hub, large ball mill end cover, blast furnace cooling stave, large rolling mill frame, large injection molding machine template, large steam turbine bearing seat, wheel hub in wind power equipment and B ...