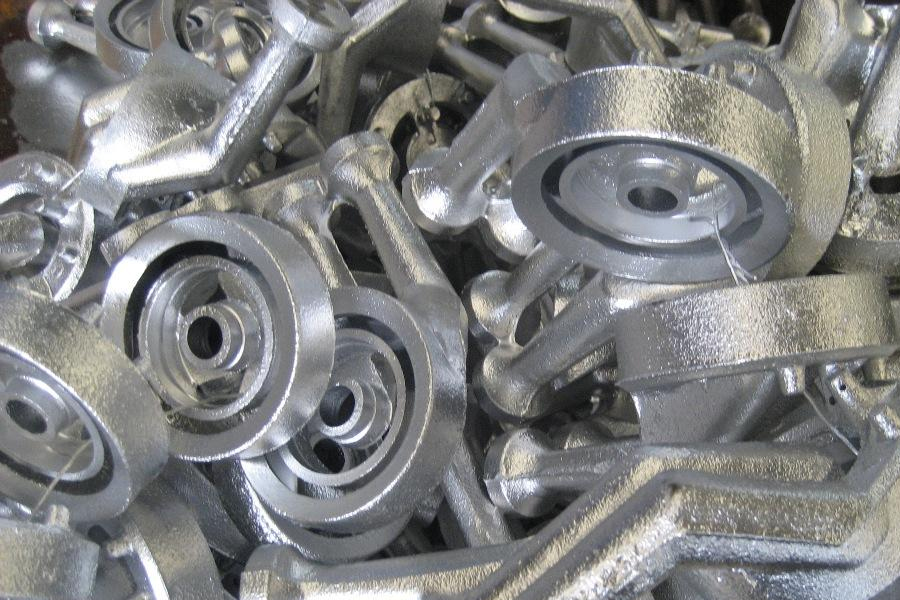

The Disassembly Method Of Mechanical Parts

The disassembly of mechanical parts is related to the safety of the parts and the efficiency of disassembly. If the method is appropriate, it will save labor and time, and at the same time protect the parts from damage. Now I will talk about the disassembly methods and precautions of the parts based ...